Mythos

Registered

Brake and Clutch Lines Removal

Aftermarket Lines Installation

Stainless steel braided lines supposedly do not flex as much as old rubber lines do. This maintains brake pressure and prevents brake fade. In my experience, I have not noticed a bit of difference in braking performance by changing to high performance lines. There is not a great deal of weight loss to be had by upgrading lines either. Unless combined with other brake upgrades, stainless steel lines are mainly for appearance, in my opinion.

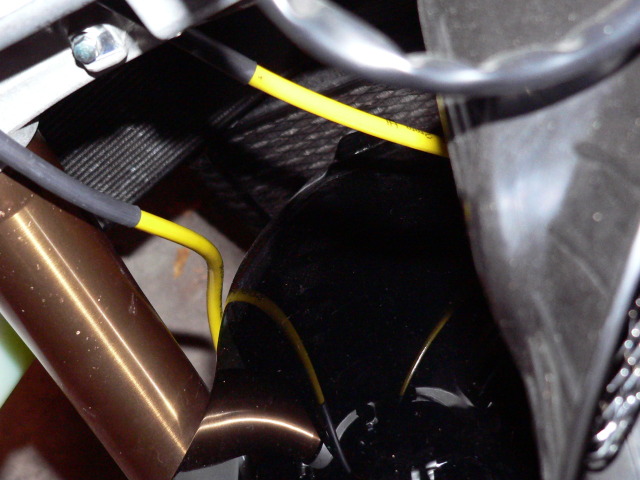

The idea behind routing your lines is to avoid situations that will cause abrasion. Rout the new lines so there will be as close to 0 contact against any moving or vibrating parts as possible. Aftermarket lines are quite stiff but there are a few points where the lines should be anchored to be certain that they do not catch on anything. Rubber lined metal clamps can be purchased at Home Depot in the hardware drawers. 1/4 inch clamps work well for Stainless steel lines.

Aftermarket brake line fittings usually have a finish on them. The finish may be protected from scratching during installation by lining sockets and wrenches with a layer of electrical tape.

Aftermarket lines may have aluminum banjo bolts that are light weight but far inferior in strength to the OEM banjo bolts. Care should be taken to not over-tighten aluminum banjo bolts. Galfer recommends torquing aluminum banjo bolts to a maximum of 12-15 foot pounds. Stainless steel banjo bolts are recommended to be torqued to a maximum of 17-20 foot pounds. I have found 15 foot pounds to work well to seal the gaskets with stainless steel banjo bolts. When Tightening aluminum banjo bolts, I would suggest torquing no more than 10 foot pounds to avoid stripping the threads. Aluminum banjo bolts must be observed closely for leaks and snugged up a little if necessary.

Brake fluid can be harmful to painted or unfinished metal and plastic. Take precautions to avoid contact with anything outside of the brake system. Always wipe up drips and wash thoroughly with water soon afterward.

When removing the old lines, you will want to hold the the fitting low after removal to drain the excess fluid. Hold the fittings high to contain any last drips inside the hose while removing the line.

The fairings, horn and triple tree guard have been removed in the photos that follow.

The fender may be covered with plastic to protect it from brake fluid drips.

Drain the front brake system completely of fluid (see GenII Front and Rear Brake Fluid, Clutch Fluid Bleed/Drain concluding paragraphs and steps 1-8).

Place the bike on a rear stand so that remaining fluid will run out vertically.

Tools:

electrical tape

drip pan

12mm wrench

8mm wrench

rag

3mm hex tool

10mm wrench

flat screwdriver

zipties

ziptie mounting plates

14mm socket

torque wrench

new brake fluid

14mm wrench

adhesive backed foam weather stripping

Front Brake Line Removal

1. Place a drip pan under the right front brake caliper. Remove banjo bolt and three washers from the banjo fitting using a 12mm wrench. A small amount of fluid will drain.

The banjo bolt and washers are arranged as shown. Bolt hex/washer/fitting/washer/fitting/washer/to caliper housing.

2. Repeat step 1 to remove the banjo fitting from the left front brake caliper. a small

amount of fluid will drain.

The banjo bolt for the left front caliper is arranged as shown. Brake caliper housing to/washer/banjo fitting/washer/banjo bolt hex.

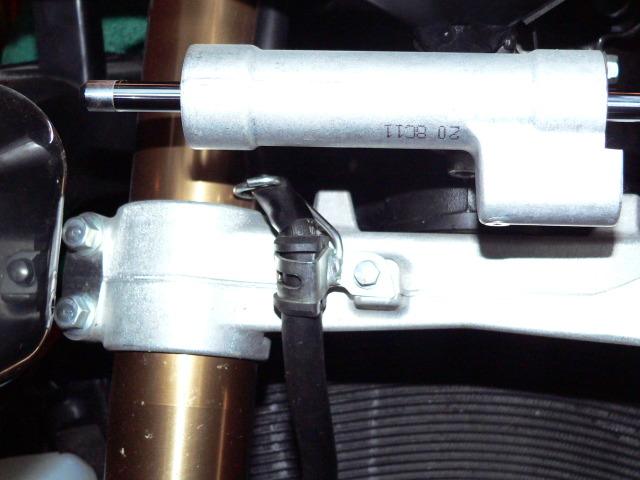

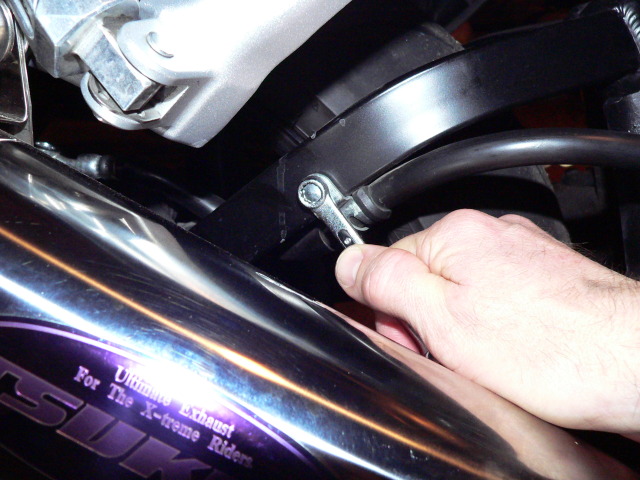

3. Use an 8mm wrench to remove the screw that fastens the front brake line retainer to

the fork clamps.

4. Use a 12mm wrench to remove the banjo bolt and two washers from the front brake

master cylinder. There should be no fluid that will drain but it is wise to put a rag under the fitting just in case.

5. Using a 3mm hex wrench, remove the three bolts marked with a red dots. (the rear

bolt that fastens the rock guard may be left on). Allow the fender to sit loose on top of the front tire.

6. Locate the brake line retainer on the right side of the fender.

Remove the brake line retainer using a 10mm wrench placed on the hex head of the screw which is located on the inside of the fender.

This is an opposite side view of the hose retainer with the screw.

7. Use a flat screwdriver to remove the plastic ring hose retainer from the top back of

the fender. This type of retainer is designed so that only half of the plug which fastens it can fit through the hole in the fender it is fastened to. Place the screwdriver blade inside the fender and press one half of the fastener inward while pressing it up through the hole in the fender at the same time.

This photo shows how the top break line retainer fastener plug is configured.

Aftermarket Front Break line Installation

I used Galfer Brake lines. Other brands may have a slightly different design. Before starting, make sure the aftermarket banjo bolts thread smoothly into the master cylinder and calipers. If they do not, you may wish to thread the bolts through a nut of the proper thread pitch (I found that one or two of my banjo bolts had threads that were a little rough, possibly from the anodizing process).

8. Assemble the double banjo bolt, three washers and front brake line banjo fittings as

shown. Note Galfer marks the ends of the brake lines that connect to the master cylinder with labels. The fitting closest to the master cylinder is straight and the fitting closest to the bolt hex is curved twelve degrees.

9. Loosely thread the banjo bolt into the master cylinder.

10. Assemble the right caliper fitting as shown with a washer on either side.

11. Loosely thread the banjo bolt into the right caliper. Repeat step 10 for the fitting to the left front brake caliper.

12. Snug up all three front brake banjo bolts finger tight so that they can be moved but will still stay put by themselves. Position the brake line fittings so that the lines are free and do not contact any other parts.

The right fitting will be best situated so that it butts against the stop molded into the right caliper housing. I would actually like to angle the fitting outward more if it was possible so that the line was held farther from the fender.

Angling the left fitting outward keeps the hose away from the fender and it also makes the brake line somewhat more visible for aesthetic purposes.

Angling the lines from the master cylinder as shown worked best for me because I have the triple tree cover and horn removed permanently. If these parts are not removed from the bike, the lines will probably have to touch somewhere.

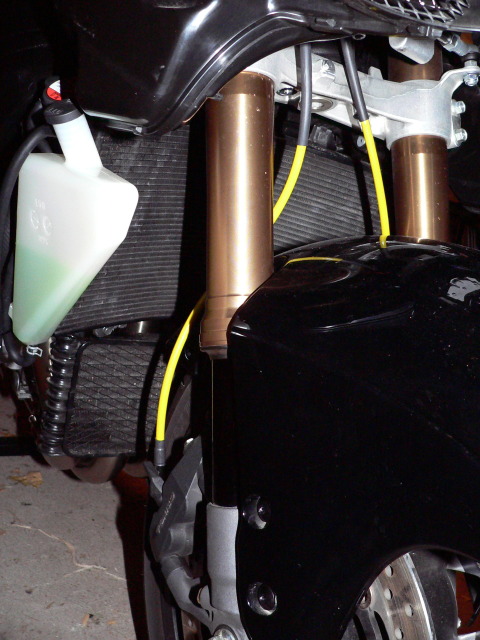

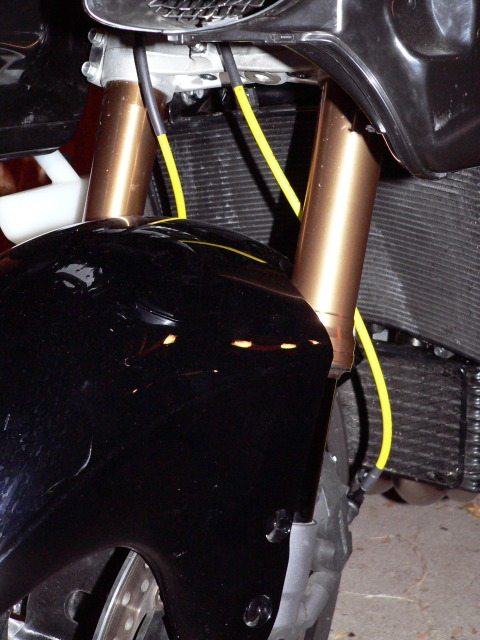

The lines do not touch the dash, throttle cables or steering damper.

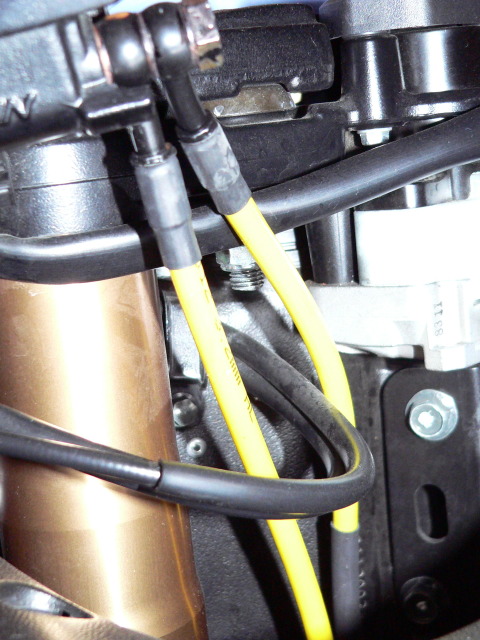

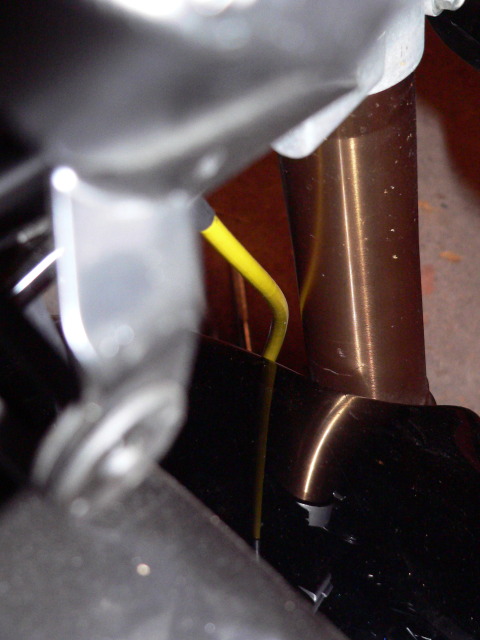

The lines are also free of the forks and fender on the right.

The left line also clears the fork and fender.

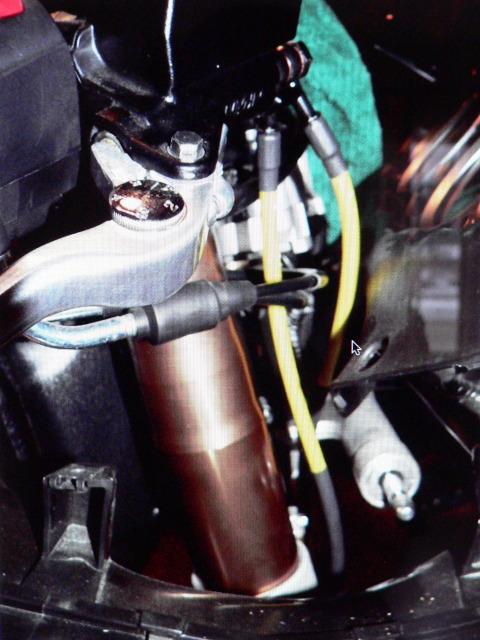

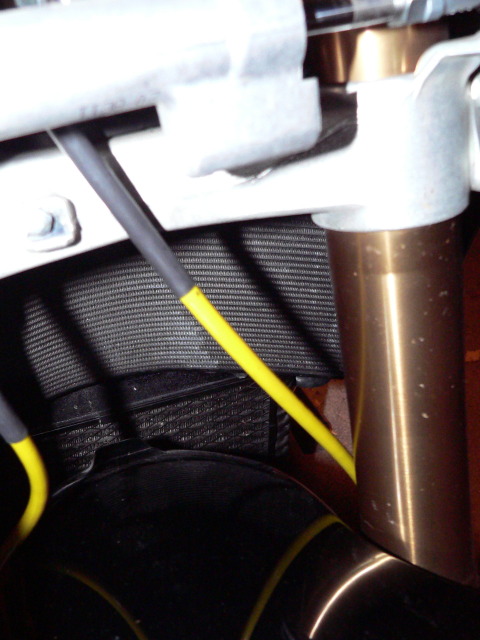

Galfer has a special vinyl protective sleeve over the lines where they are likely to touch the triple tree.

The Galfer kit also includes a brake line retainer that mounts to the triple tree where the OEM brake line retainer was located. I did not use the Galfer retainer for my setup but I made my own out of zipties and a ziptie mounting plate.

13. If any fairings or meter panel pieces were removed, install them. Turn the steering from lock to lock to test for brake line clearance. It is optimum that the brake lines do not touch anything throughout the entire steering radius. However, it should be noted that the OEM throttle cables touch the lower meter panel when the steering is turned hard to the left (at least they do on my GenII). There has been no recall to correct that. If the aftermarket lines touch a little bit in a turn or if they gently rest against the horn, I think that is probably okay. If they are binding or abrading, obviously their position will need to be adjusted somehow.

14. When acceptable brake line clearance is achieved, use a 14mm socket and torque wrench all 3 front brake line banjo bolts according to the brake line manufacturers specifications. Fill the front brake system with new brake fluid and bleed it thoroughly of air (see GenII Front and Rear Brake Fluid, Clutch Fluid Bleed/Drain, steps steps 1-12 and the final remarks under Draining Brake and Clutch Fluid).

Rear Brake Line Removal

Drain the rear brake system of all fluid (see GenII Front and Rear Brake Fluid, Clutch Fluid Bleed/Drain, steps 13-21 and the concluding remarks on Draining Brake and Clutch Fluid ).

15. Use an 8mm wrench to remove the rear brake line retainer from the swing arm.

16. Use a 12mm wrench to remove the banjo bolt from the rear brake master cylinder.

Wrap a rag around the fitting while removing the banjo bolt so that no fluid runs on painted surfaces surrounding the rear master cylinder.

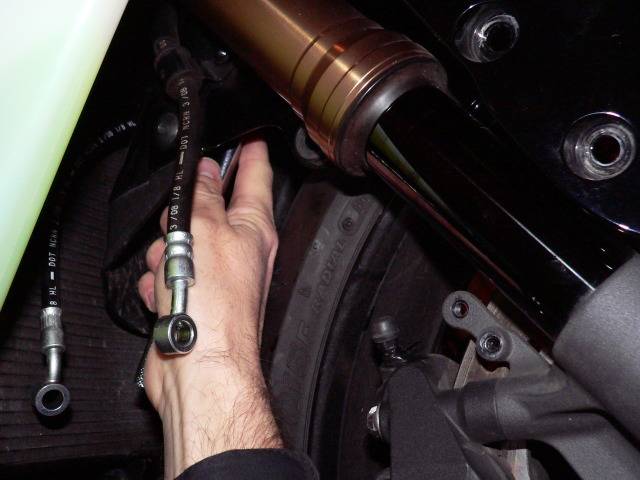

17. Use a 12mm wrench to remove the banjo bolt from the rear brake caliper. Remove

the rear brake line.

Aftermarket Rear Brake Line Install

18. Arrange the banjo bolt with one washer on each side of the fitting that will go to the rear brake master cylinder. Be sure that the bolt you use has the proper thread. The rear brake master cylinder on the Hayabusa has finer thread than the rear brake caliper.

You may use a rear brake light pressure switch as shown in this picture rather than a banjo bolt. The pressure switch and washers are placed the same as would an ordinary banjo bolt.

19. Connect the the rear brake line to the rear brake master cylinder using a 14mm wrench to tighten the aftermarket banjo bolt. Install the fitting so that the stem is between the stops on the back of the master cylinder.

20. Arrange the rear brake caliper banjo bolt with a washer on each side of the fitting. Be sure that you are using the banjo bolt with the larger thread which is specifically for the Hayabusa rear brake caliper. Install the fitting to the rear brake caliper so that the stem is between the stops on the caliper housing.

21. Use a 14mm socket and torque wrench both rear brake banjo bolts according to the brake line manufacturers specifications. If a rear brake light pressure switch is used on the master cylinder, it will not be possible to use a torque wrench on it. You will have to estimate the torque and use an ordinary wrench. Fill the front brake system with new brake fluid and bleed it thoroughly of air (see GenII Front and Rear Brake Fluid, Clutch Fluid Bleed/Drain, steps steps 1-12 and the final remarks under Draining Brake and Clutch Fluid).

Clutch Line Removal

Drain all fluid from the clutch system (See GenII Front and Rear Brake Fluid, Clutch Fluid Bleed/Drain, steps 22-32 and concluding remarks on Draining Brake and Clutch Fluid).

22. Place a drip pan under the clutch slave cylinder.

23. Use a 12mm wrench to loosen the banjo bolt on the clutch slave cylinder. Allow any remaining clutch fluid to drain out.

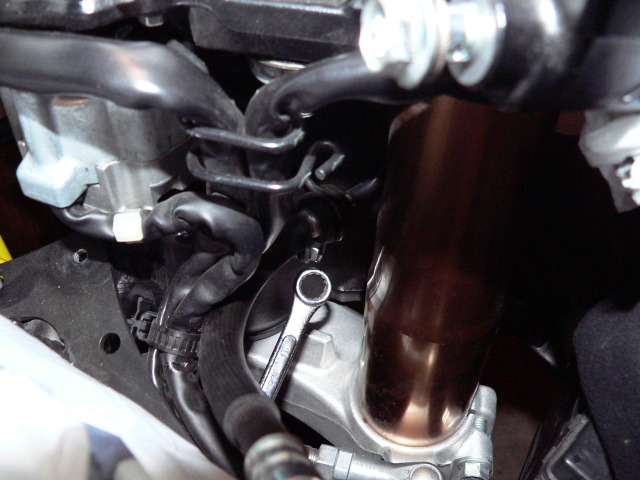

The banjo bolts, gaskets and the brake line fitting are properly arranged as shown with one gasket on each side of the fitting.

24. Use a 10mm wrench to remove the clutch line retainer from the frame.

The clutch line retainer comes off of the rubber grommet on the solid portion of the clutch line.

25. Use a 12mm wrench to remove the banjo bolt from the clutch master cylinder.

26. There is a second clutch line retainer located on the exterior of the steering pivot above the triple tree. Use a 10mm wrench to remove it and then remove the clutch line.

Aftermarket Lines Installation

Stainless steel braided lines supposedly do not flex as much as old rubber lines do. This maintains brake pressure and prevents brake fade. In my experience, I have not noticed a bit of difference in braking performance by changing to high performance lines. There is not a great deal of weight loss to be had by upgrading lines either. Unless combined with other brake upgrades, stainless steel lines are mainly for appearance, in my opinion.

The idea behind routing your lines is to avoid situations that will cause abrasion. Rout the new lines so there will be as close to 0 contact against any moving or vibrating parts as possible. Aftermarket lines are quite stiff but there are a few points where the lines should be anchored to be certain that they do not catch on anything. Rubber lined metal clamps can be purchased at Home Depot in the hardware drawers. 1/4 inch clamps work well for Stainless steel lines.

Aftermarket brake line fittings usually have a finish on them. The finish may be protected from scratching during installation by lining sockets and wrenches with a layer of electrical tape.

Aftermarket lines may have aluminum banjo bolts that are light weight but far inferior in strength to the OEM banjo bolts. Care should be taken to not over-tighten aluminum banjo bolts. Galfer recommends torquing aluminum banjo bolts to a maximum of 12-15 foot pounds. Stainless steel banjo bolts are recommended to be torqued to a maximum of 17-20 foot pounds. I have found 15 foot pounds to work well to seal the gaskets with stainless steel banjo bolts. When Tightening aluminum banjo bolts, I would suggest torquing no more than 10 foot pounds to avoid stripping the threads. Aluminum banjo bolts must be observed closely for leaks and snugged up a little if necessary.

Brake fluid can be harmful to painted or unfinished metal and plastic. Take precautions to avoid contact with anything outside of the brake system. Always wipe up drips and wash thoroughly with water soon afterward.

When removing the old lines, you will want to hold the the fitting low after removal to drain the excess fluid. Hold the fittings high to contain any last drips inside the hose while removing the line.

The fairings, horn and triple tree guard have been removed in the photos that follow.

The fender may be covered with plastic to protect it from brake fluid drips.

Drain the front brake system completely of fluid (see GenII Front and Rear Brake Fluid, Clutch Fluid Bleed/Drain concluding paragraphs and steps 1-8).

Place the bike on a rear stand so that remaining fluid will run out vertically.

Tools:

electrical tape

drip pan

12mm wrench

8mm wrench

rag

3mm hex tool

10mm wrench

flat screwdriver

zipties

ziptie mounting plates

14mm socket

torque wrench

new brake fluid

14mm wrench

adhesive backed foam weather stripping

Front Brake Line Removal

1. Place a drip pan under the right front brake caliper. Remove banjo bolt and three washers from the banjo fitting using a 12mm wrench. A small amount of fluid will drain.

The banjo bolt and washers are arranged as shown. Bolt hex/washer/fitting/washer/fitting/washer/to caliper housing.

2. Repeat step 1 to remove the banjo fitting from the left front brake caliper. a small

amount of fluid will drain.

The banjo bolt for the left front caliper is arranged as shown. Brake caliper housing to/washer/banjo fitting/washer/banjo bolt hex.

3. Use an 8mm wrench to remove the screw that fastens the front brake line retainer to

the fork clamps.

4. Use a 12mm wrench to remove the banjo bolt and two washers from the front brake

master cylinder. There should be no fluid that will drain but it is wise to put a rag under the fitting just in case.

5. Using a 3mm hex wrench, remove the three bolts marked with a red dots. (the rear

bolt that fastens the rock guard may be left on). Allow the fender to sit loose on top of the front tire.

6. Locate the brake line retainer on the right side of the fender.

Remove the brake line retainer using a 10mm wrench placed on the hex head of the screw which is located on the inside of the fender.

This is an opposite side view of the hose retainer with the screw.

7. Use a flat screwdriver to remove the plastic ring hose retainer from the top back of

the fender. This type of retainer is designed so that only half of the plug which fastens it can fit through the hole in the fender it is fastened to. Place the screwdriver blade inside the fender and press one half of the fastener inward while pressing it up through the hole in the fender at the same time.

This photo shows how the top break line retainer fastener plug is configured.

Aftermarket Front Break line Installation

I used Galfer Brake lines. Other brands may have a slightly different design. Before starting, make sure the aftermarket banjo bolts thread smoothly into the master cylinder and calipers. If they do not, you may wish to thread the bolts through a nut of the proper thread pitch (I found that one or two of my banjo bolts had threads that were a little rough, possibly from the anodizing process).

8. Assemble the double banjo bolt, three washers and front brake line banjo fittings as

shown. Note Galfer marks the ends of the brake lines that connect to the master cylinder with labels. The fitting closest to the master cylinder is straight and the fitting closest to the bolt hex is curved twelve degrees.

9. Loosely thread the banjo bolt into the master cylinder.

10. Assemble the right caliper fitting as shown with a washer on either side.

11. Loosely thread the banjo bolt into the right caliper. Repeat step 10 for the fitting to the left front brake caliper.

12. Snug up all three front brake banjo bolts finger tight so that they can be moved but will still stay put by themselves. Position the brake line fittings so that the lines are free and do not contact any other parts.

The right fitting will be best situated so that it butts against the stop molded into the right caliper housing. I would actually like to angle the fitting outward more if it was possible so that the line was held farther from the fender.

Angling the left fitting outward keeps the hose away from the fender and it also makes the brake line somewhat more visible for aesthetic purposes.

Angling the lines from the master cylinder as shown worked best for me because I have the triple tree cover and horn removed permanently. If these parts are not removed from the bike, the lines will probably have to touch somewhere.

The lines do not touch the dash, throttle cables or steering damper.

The lines are also free of the forks and fender on the right.

The left line also clears the fork and fender.

Galfer has a special vinyl protective sleeve over the lines where they are likely to touch the triple tree.

The Galfer kit also includes a brake line retainer that mounts to the triple tree where the OEM brake line retainer was located. I did not use the Galfer retainer for my setup but I made my own out of zipties and a ziptie mounting plate.

13. If any fairings or meter panel pieces were removed, install them. Turn the steering from lock to lock to test for brake line clearance. It is optimum that the brake lines do not touch anything throughout the entire steering radius. However, it should be noted that the OEM throttle cables touch the lower meter panel when the steering is turned hard to the left (at least they do on my GenII). There has been no recall to correct that. If the aftermarket lines touch a little bit in a turn or if they gently rest against the horn, I think that is probably okay. If they are binding or abrading, obviously their position will need to be adjusted somehow.

14. When acceptable brake line clearance is achieved, use a 14mm socket and torque wrench all 3 front brake line banjo bolts according to the brake line manufacturers specifications. Fill the front brake system with new brake fluid and bleed it thoroughly of air (see GenII Front and Rear Brake Fluid, Clutch Fluid Bleed/Drain, steps steps 1-12 and the final remarks under Draining Brake and Clutch Fluid).

Rear Brake Line Removal

Drain the rear brake system of all fluid (see GenII Front and Rear Brake Fluid, Clutch Fluid Bleed/Drain, steps 13-21 and the concluding remarks on Draining Brake and Clutch Fluid ).

15. Use an 8mm wrench to remove the rear brake line retainer from the swing arm.

16. Use a 12mm wrench to remove the banjo bolt from the rear brake master cylinder.

Wrap a rag around the fitting while removing the banjo bolt so that no fluid runs on painted surfaces surrounding the rear master cylinder.

17. Use a 12mm wrench to remove the banjo bolt from the rear brake caliper. Remove

the rear brake line.

Aftermarket Rear Brake Line Install

18. Arrange the banjo bolt with one washer on each side of the fitting that will go to the rear brake master cylinder. Be sure that the bolt you use has the proper thread. The rear brake master cylinder on the Hayabusa has finer thread than the rear brake caliper.

You may use a rear brake light pressure switch as shown in this picture rather than a banjo bolt. The pressure switch and washers are placed the same as would an ordinary banjo bolt.

19. Connect the the rear brake line to the rear brake master cylinder using a 14mm wrench to tighten the aftermarket banjo bolt. Install the fitting so that the stem is between the stops on the back of the master cylinder.

20. Arrange the rear brake caliper banjo bolt with a washer on each side of the fitting. Be sure that you are using the banjo bolt with the larger thread which is specifically for the Hayabusa rear brake caliper. Install the fitting to the rear brake caliper so that the stem is between the stops on the caliper housing.

21. Use a 14mm socket and torque wrench both rear brake banjo bolts according to the brake line manufacturers specifications. If a rear brake light pressure switch is used on the master cylinder, it will not be possible to use a torque wrench on it. You will have to estimate the torque and use an ordinary wrench. Fill the front brake system with new brake fluid and bleed it thoroughly of air (see GenII Front and Rear Brake Fluid, Clutch Fluid Bleed/Drain, steps steps 1-12 and the final remarks under Draining Brake and Clutch Fluid).

Clutch Line Removal

Drain all fluid from the clutch system (See GenII Front and Rear Brake Fluid, Clutch Fluid Bleed/Drain, steps 22-32 and concluding remarks on Draining Brake and Clutch Fluid).

22. Place a drip pan under the clutch slave cylinder.

23. Use a 12mm wrench to loosen the banjo bolt on the clutch slave cylinder. Allow any remaining clutch fluid to drain out.

The banjo bolts, gaskets and the brake line fitting are properly arranged as shown with one gasket on each side of the fitting.

24. Use a 10mm wrench to remove the clutch line retainer from the frame.

The clutch line retainer comes off of the rubber grommet on the solid portion of the clutch line.

25. Use a 12mm wrench to remove the banjo bolt from the clutch master cylinder.

26. There is a second clutch line retainer located on the exterior of the steering pivot above the triple tree. Use a 10mm wrench to remove it and then remove the clutch line.

Last edited by a moderator: