My seats were getting a little tired, so I was looking to freshen them up a bit. I looked into the aftermarket seats out there, but have never had too much of a problem on the factory seat, so I decided to recover what I had. There are lots of pre-made seat covers out there on ebay etc, but most seemed to run over $100 for the covers, and you still had to get them put on to the seat pans. In the end, I bought some carbon-fibre look marine vinyl at a local apholstory store for $16/yd and bought a pneumatic apholstory staple gun for about $70 at home depot. This way, I figure I saved money, and I get to keep the stapler for future projects to boot!

The seat before:

You can see the material was getting thin in spots and was starting to crack. I had a seat start to look like this on my last bike during a trip to Nova Scotia, and by the time I got back home it was completely destroyed. (about 2000 miles later)

Recovering was a fairly simple task, the old covers are stapled on, so it's just a matter of removing the staples with a thin screwdriver and some needle nose pliers. I laid the bare seat upside down on the material, and cut out a rough outline, allowing plenty of excess. It's important to pay attention to the bias of the material at this point so the pattern on the material is layed out correctly.

Once the material is cut, just fasten the material to the back centre with a few staples, and lightly stretch the fabric and do the same in the front. I then moved to the sides and worked back and forth, stretching the fabric as I went. The hardest part is the corners, where you need to bunch the extra fabric together under the seat, stretching carefully in such a way as to hide the pleats under the seat. There is some trial and error here, but the good new is that you can always remove staples and start a section over if it isn't perfect.

All in all a little patience is required, but anyone can do it. I would only caution that you use a pneumatic stapler. I tried with a hand stapler, and it didn't have the power to to the job properly, plus it couldn't get into the corners where the staples are most important. The whole job took less than 2 hours once I had the tools and materials.

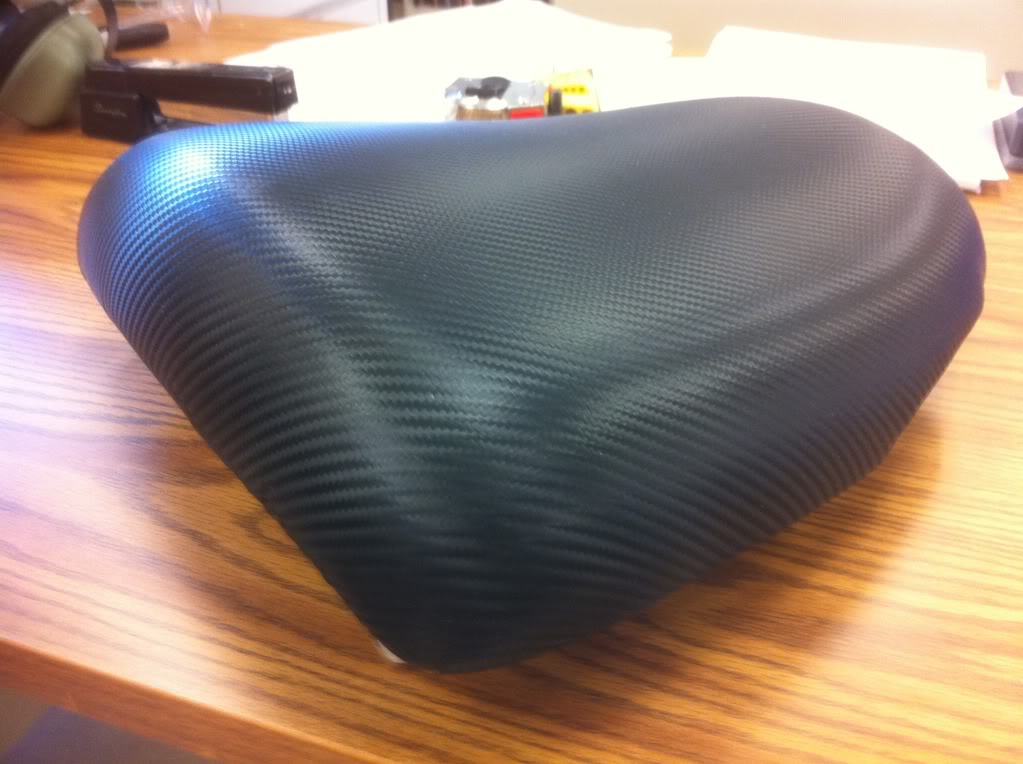

The final results:

The seat before:

You can see the material was getting thin in spots and was starting to crack. I had a seat start to look like this on my last bike during a trip to Nova Scotia, and by the time I got back home it was completely destroyed. (about 2000 miles later)

Recovering was a fairly simple task, the old covers are stapled on, so it's just a matter of removing the staples with a thin screwdriver and some needle nose pliers. I laid the bare seat upside down on the material, and cut out a rough outline, allowing plenty of excess. It's important to pay attention to the bias of the material at this point so the pattern on the material is layed out correctly.

Once the material is cut, just fasten the material to the back centre with a few staples, and lightly stretch the fabric and do the same in the front. I then moved to the sides and worked back and forth, stretching the fabric as I went. The hardest part is the corners, where you need to bunch the extra fabric together under the seat, stretching carefully in such a way as to hide the pleats under the seat. There is some trial and error here, but the good new is that you can always remove staples and start a section over if it isn't perfect.

All in all a little patience is required, but anyone can do it. I would only caution that you use a pneumatic stapler. I tried with a hand stapler, and it didn't have the power to to the job properly, plus it couldn't get into the corners where the staples are most important. The whole job took less than 2 hours once I had the tools and materials.

The final results: