Velix

Registered

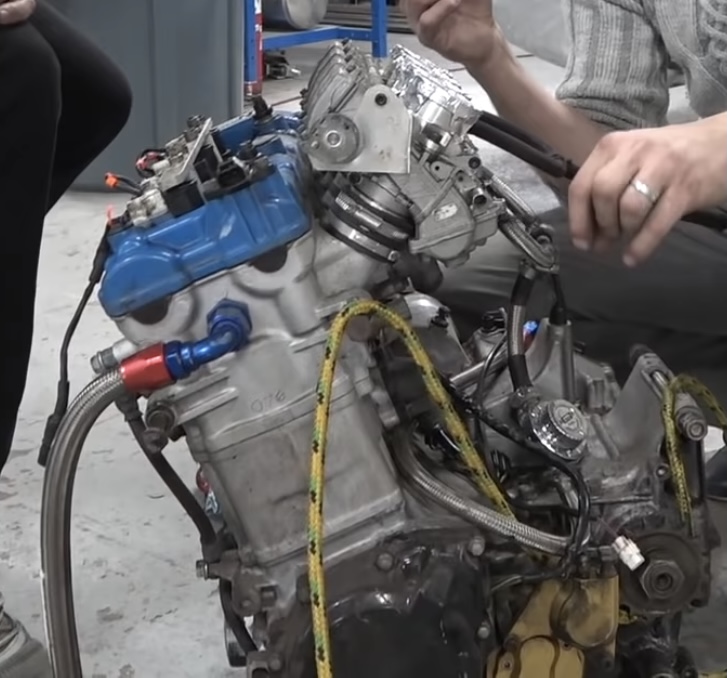

Hey everyone, I’ve been reading through whatever I can find about oil system mods for a gen 1, but wanted some opinions since mine has a full dry sump system.

*So, first of all, I am going to be running a larger oil sprocket as recommended by the dry sump manufacturer. As it’s being put into a car, dry sump was essential.

*Secondly, I’m going to be blocking the oiler to the stator as I’m going to run a standard gm alternator, and need the area to stay dry.

*Third, I will be restricting the flow to the turbo, removing the plug from behind the filter, and making the area flow around the filter as recommended below: (from another forum)

My question is I guess, knowing my setup, which of these mods would you all recommend I do? I also found a Hayabusa engine that put a large drain from the head and wondered if that would be necessary as well.

Hopefully you all have some great advice for me and thanks for the help!

*So, first of all, I am going to be running a larger oil sprocket as recommended by the dry sump manufacturer. As it’s being put into a car, dry sump was essential.

*Secondly, I’m going to be blocking the oiler to the stator as I’m going to run a standard gm alternator, and need the area to stay dry.

*Third, I will be restricting the flow to the turbo, removing the plug from behind the filter, and making the area flow around the filter as recommended below: (from another forum)

The oil mods:

There are a few things a guy can do to these engines to get more oil where its needed. Take note that these mods are for engines making* 2-3+ times OEM HP. Truth be known the OEM oiling system is very adequate and capable of taking a bike well 100K miles without issues. Some of these mods should not be done for daily drivers and all should be done at your own risk.

There are 2 very important terms dealing with an oil system. These terms are ‘FLOW’ and ‘PRESSURE’. Think of filling a 2-5 gallon buckets with water. You can use a high pressure 1” hose with 300 psi and fill it in about 2 seconds…..or use another 5 gallon bucket to dump into the other. The bucket poured has almost zero pressure but massive flow. Two different ways to fill a bucket in the same time but one uses flow and the other uses pressure. These concepts are critical to the busa oil system.*

The whole idea of* ‘improving’ the busa oil system is to provide more oil to the bearings. More oil directly equates to less bearing failure even with massive load stresses, and in the event of a bearing failure can lessen the damage.

First, lets take a look at the heart. It consists of the pump and regulator.

The regulators job is to regulate pressure both low and high. The pumps job is to pump oil…..seems like a simple concept….but pressure in the system is generated by restrictions so any modification designed to decrease oil flow (jet reductions) in hopes that it will send more oil to the bearings will fail. AS with the APE high volume pump gear. It all goes out the regulator……

Look at it this way:

(pump puts oil IN the system, everything else bleeds oil off)

-Pump (100% in flow to system* [OEM GEAR]) to regulator (-33 out flow) - jets, coolers, and secondary oiling (-33 out flow) main and rod bearings (-33 out flow).

One of the common mods is to restrict jets…..but heres what happens:

-Pump (100% in flow to system* [OEM GEAR]) to regulator (-55 out flow) - jets, coolers, and secondary oiling (-11 out flow) – main and rod bearings (-33 out flow)

With high flow pump gear:

-Pump (130% in flow to system* [APE GEAR]) to regulator (-85 out flow) - jets, coolers, and secondary oiling (-11 out flow) – main and rod bearings (-33 out flow)

Basically all that happens is the jets flow less, regulator flows more and main and rod bearings get EXACTLY the same! This will be true IF the OEM regulator has enough flow capability to outflow. IT IS MY OPINION THAT THE REGULATOR BY DESIGN WAS NOT MADE TO BE ABLE TO FULLY REGULATE SYSTEM PRESSURE! This is only guess….and the fact that Suzuki has a block in the regulator piston so it only goes ½ way down the out jets…..hummmmm. I believe even with the OEM pump gear the pump can flow more oil than the regulator can vent out.* These are just assumptions on my part…..

1st mod. APE high volume gear.

2nd Billet ‘high pressure’ oil regulator OR (and what I do) make a restrictor to the oil pressure regulator by using a washer with an inside hole of ¼” that sits on top of the regulator.

Example with high volume pump, restricted or high pressure regulator only:

-Pump (130% in flow to system* [APE GEAR]) to regulator (-33 [now limited] out flow) - jets, coolers, and secondary oiling (-48 out flow) – main and rod bearings (-48 out flow)

Clearly more oil is going to the bearings…..BUT also more oil is going to the head, transmission, piston cooling jets and other items that DO NOT NEED EXTRA FLOW!

Mod 3

Restrictions of the piston cooling jets.

I have used 2 methods for restriction, soldering the ends and drilling and putting a.032 drill in the end and pinching the tube around the bit. Soldering the ends looked cleaner but was time consuming and a huge pain. I recommend the pinch method. I have not done flow tests but can say that with these restricted to about .030-.035 will at higher pressure….will flow near the same amount of oil as OEM jets will with the OEM pump/reg. Many people block these 100% with no problems....truth is all the oil going out the rods and mains gets slung around and will oil the pistons, pins and cylinders. Because I run 5 miles wide open I only restrict mine....if I did 1320 I would block them completely.

Mod 4

Blocking the stator jet

Bad idea for the daily driver….good idea for the drag racer (or LSR).

Mod 5

Reducing oil to the head.

(this I read about somewhere else….)

There is a through bolt that supplies oil to the head. Now that the pump and regulator flow more if left OEM the head will receive much more oil than needed. Drill and tap the end of the bolt and use a .125 jet to restrict flow.

Mod 6

Block oiling to the counterbalancer.

If you have a balanced crank and removed the counterbalancer you will also need to block the passages or starve the motor. Easiest (and cheap) method is to use the APE counter block off. APE

Now with the HV gear, Modded regulator AND restricted secondary oiling:

-Pump (130% in flow to system* [APE GEAR]) to regulator (-33 [now limited] out flow) - jets, coolers, and secondary oiling (-28 out flow) – main and rod bearings (-68 out flow)

As you can see much more oil is now going to the bearings and basically the same is going to secondary systems.

Mod 7

Problems with Koenig:

Awesome pan….but…

A.***The o-ring on the pick up swivel (at least on mine) is slightly smaller then what it should have been. This could of caused bubbles to be introduced into the system. I have seen 2 instances where you could blow air past the o-ring. Something to look for….I would bet someone with oil fluctuations is due to this smallish Oring and* couldn’t find what the prob was…..or others that lost motors/bearings because of this.*

B.***The bolt that limits the swing travel…..they used an off the shelf screw that protrudes about 75% into the pickup tube!!!!! Remove it and cut it off so only a small nub in in the pipe. Hard for me to believe they did this….

C.***Remove the prescreen and put a radius on the pickup intake end block. This will allow a much higher oil volume to be taken up without cavitation.

Mod 8

Removing the castings sides of the OEM oil restrictor behind filter.

When removing the oil cooler you will need to remove the restrictor plug (oil goes IN the filter and back to the motor* through the pipe) The interesting thing that Suzuki did was include the pipe with the oil restirctior on one side….and the oil from the oil cooler on the opposite. I do not think this was done by accident. I believe it was to balance oil flow on both sides of the filter. If you remove the cooler and restrictor use a die grinder with carbide tip to knock down the walls allowing oil to be able to flow around the base of the filter unobstructed. I also drill out the threads so the oil pipe now has a smooth bore.

Before

after

Mod 9

Radius the oil filter discharge pipe.

The end of the pipe the filter screws on is squared…..Think of this flow the same way velocity stacks work. By putting a slight radii on the end of the pipe will help oil flow back into the motor.

Modifying the ease of the flow now translates into MORE pump flow:

-Pump (136% in flow to system* [APE GEAR]) to regulator (-33 [now limited] out flow) - jets, coolers, and secondary oiling (-31 out flow) – main and rod bearings (-71 out flow)

Increasing flow to the bearings:

Mod 10

I have done some flow test….sounds crazy but I use a garden hose and a tape measure.* Connect a garden hose to the oil filter IN pipe and turn it on (low). You can measure the water stream coming from each bearing supply hole (shells off). (Note; you can also check flow of piston jets the same way)

I have noticed slightly less flow going to the 1 and* 2 bearing. You will notice that all other bearings are fed from a large primary gallery….and then takes 2-90 degree turns and goes waaaay down in size.

Drill out this passage to 5/16” all the way to the end (and no more!). Tap and plug this hole. I don’t BUT it would also be a good idea to remove the plug doing the same to its adjoining ‘feeding’ passage (also small).

Mod 11

Increasing the ‘slit’ width under the shells

Its easy to see that with the shells installed part of the oil hole into the shell is blocked by the castings below. I do not do this mod but many use a fine cut off wheel to remove some stock from the sides to expose more of the shell hole to the feed below.

Mod 12

Modifying the bearing shells.

I have done this mod but it makes me uneasy. Truth is I don’t like to handle these shells let alone drill on them. I have drilled additional holes….and oblonged existing holes. Using the now available gen II bearings with long holes is the only way to go!!!!

Mod 13

The Gen II crank

The Gen II crank has grooves around the main journals. This, along with the long holes in the gen II bearings provides significantly more oil to the rods. Suzuki CLEARLY recognized the need to provide more oil to the rods by this change. This change made many of the before mentioned oil mods unnecessary (but not entirely).

I have (to my knowledge) the first Gen I crank that has had the mains fluted like the Gen II (on its way in a week or so) and was done because of the significant improvement in oiling. Crankshaft repair, outboard marine, motorcycles, circle track, quarter mile and imports, billet crankshaft - We Fix Crankshafts - Marine Crankshaft, Inc.

Mod 14

Bearing tolerances

Ok, this is not really a mod but important. Oil like all liquids under pressure will FLOW TO THE POINT OF LEAST RESISTANCE! Because oil flows to the mains FIRST and then the rods if you have your mains loose and your rods tight all the oil will flow out the crank and starve the rods. So in building these engines you need to have your mains tighter than your rods…..but not so loose you would drop pressure to the mains! I personally run on the tight side of tolerance for the main and closer to the looser spec on the rods. Get this wrong and you will smoke the motor. This is why engine builders get paid the $$$$....because they know this poop.

Mod 15

Restrict oil to the turbo!!!!

You are tapping a line off the main artery of the motor. You must run a restrictor in the line and the turbo doesn’t need 50 gallons of oil running through it!

In closing, I made most of this up, may of missed some important ones or was way off base in calculations.

Take everything I say with a grain of salt….

~JH

My question is I guess, knowing my setup, which of these mods would you all recommend I do? I also found a Hayabusa engine that put a large drain from the head and wondered if that would be necessary as well.

Hopefully you all have some great advice for me and thanks for the help!