Hey guys, figured I'd come and introduce myself and why I'm here. I don't own a busa nor have I even owned a street bike. I am an avid enthusiast of automotive engineering and going fast. The 1300 busa design is ridiculously impressive, the torque numbers are good but it's not a true testament to how good it is. The true feat is maintaining that torque for almost 7000 rpm not to mention it doesn't even have VVT! Imagine if it was a 2.6 v8  a constant 200 ft-lbs for 7000 rpm and in a 200 lb package?! It's just insane to think about... or is? Radical, hartley and synergy already have motors designed around this but they cost about $30-40 grand for a long block so it's definitely possible.

a constant 200 ft-lbs for 7000 rpm and in a 200 lb package?! It's just insane to think about... or is? Radical, hartley and synergy already have motors designed around this but they cost about $30-40 grand for a long block so it's definitely possible.

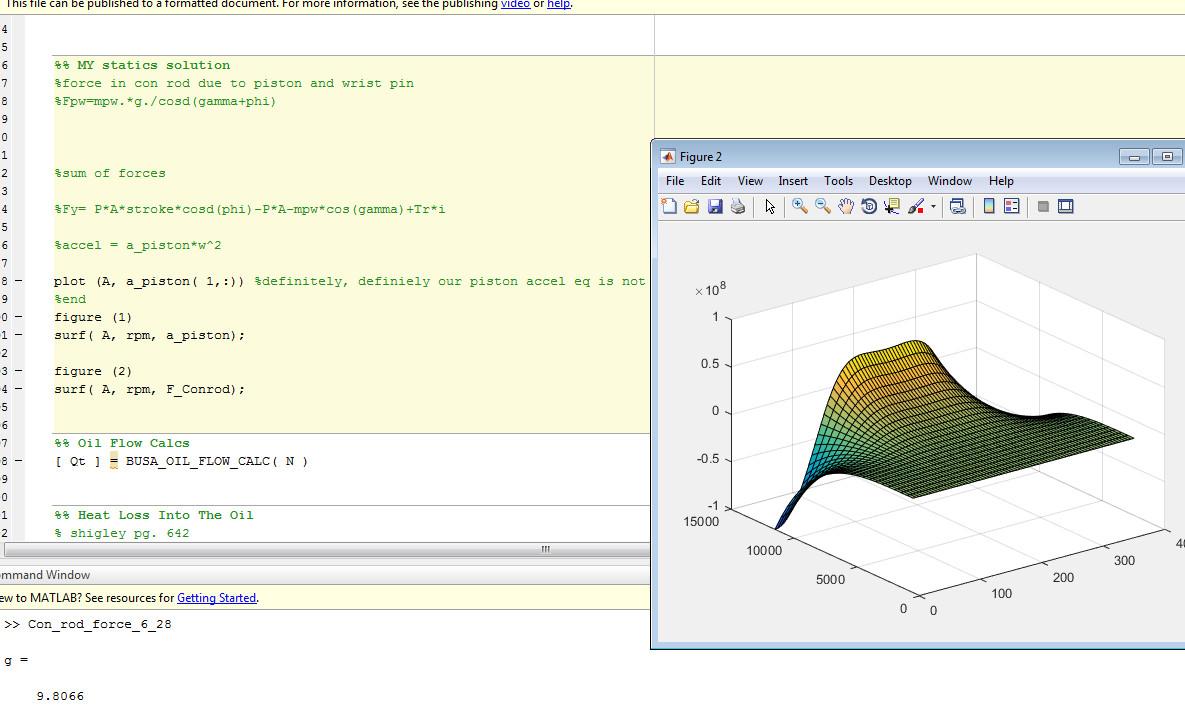

Who the hell do I think I am?! I have a masters in mechanical engineering although most of my time in school was spent designing the technical architecture of our Formula SAE car but I specialized in powertrain and suspension design. I currently have access to a suite of engineering software, a 5-axis mill and a competent machinist. I've got the conceptual design mostly finished so I know I can design it and I know I can make it but the question is if I can do it affordably. Right now I'm estimating about $10k for a finished long block. I really want to get the design done for under $1k so that I can have a big buffer in cse the quotes for manufacturing are much higher than expected. $1k is quite a challenge without buying a full motor so I came here looking for help. I need help finding busted parts, broken cranks and windowed blocks to get stock dimensions from.

I've uploaded a couple fun pics, take them with a grain of salt. There is a TON of math and logistics going on behind these pictures. The pic of the hartley V8 is not mine, I just added it to get people psyched.

a constant 200 ft-lbs for 7000 rpm and in a 200 lb package?! It's just insane to think about... or is? Radical, hartley and synergy already have motors designed around this but they cost about $30-40 grand for a long block so it's definitely possible.

a constant 200 ft-lbs for 7000 rpm and in a 200 lb package?! It's just insane to think about... or is? Radical, hartley and synergy already have motors designed around this but they cost about $30-40 grand for a long block so it's definitely possible.Who the hell do I think I am?! I have a masters in mechanical engineering although most of my time in school was spent designing the technical architecture of our Formula SAE car but I specialized in powertrain and suspension design. I currently have access to a suite of engineering software, a 5-axis mill and a competent machinist. I've got the conceptual design mostly finished so I know I can design it and I know I can make it but the question is if I can do it affordably. Right now I'm estimating about $10k for a finished long block. I really want to get the design done for under $1k so that I can have a big buffer in cse the quotes for manufacturing are much higher than expected. $1k is quite a challenge without buying a full motor so I came here looking for help. I need help finding busted parts, broken cranks and windowed blocks to get stock dimensions from.

I've uploaded a couple fun pics, take them with a grain of salt. There is a TON of math and logistics going on behind these pictures. The pic of the hartley V8 is not mine, I just added it to get people psyched.