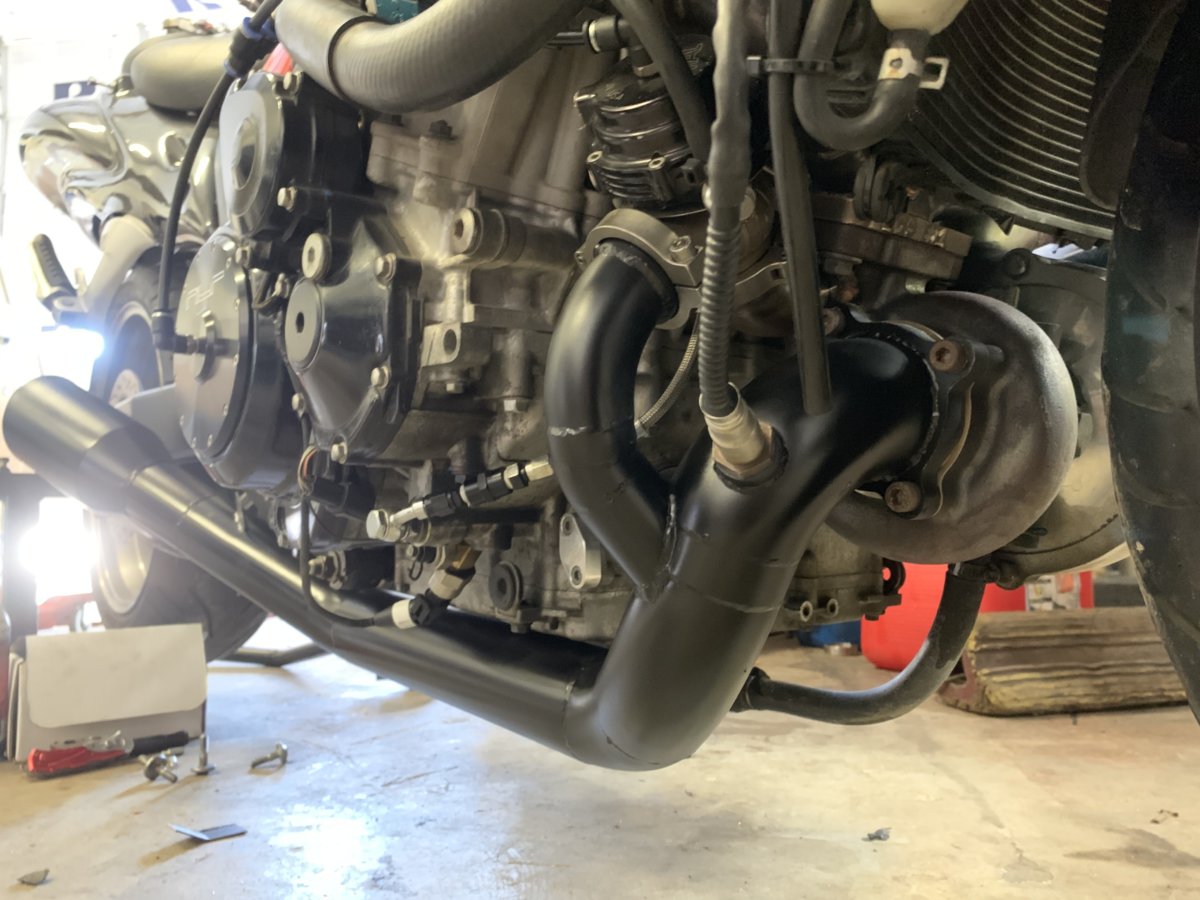

I also took some time to make a better looking, fitting and presumably better flowing full exhaust. I’m really happy how it turned out.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Lucy turbo build, and testing

- Thread starter Boosted Cycle Perf

- Start date

More options

Meta tagsLastly, I had a rash of guys needing relocation brackets, so I designed and cut some light weight brackets.

How much do you want for one of those shipped to Florida 33569. PM with price, please and thanks!Lastly, I had a rash of guys needing relocation brackets, so I designed and cut some light weight brackets.

View attachment 1604625

View attachment 1604626

View attachment 1604627

Sorry for the delay. I have to tweak them just a touch. The spacing between the two groups of 9 holes is off by maybe 1/16”. Bolts slide through but at a slight angle. It bothers me... I have a bunch useful little aluminum parts/brackets in testing. I plan to do a big sale and roll them all out at once.How much do you want for one of those shipped to Florida 33569. PM with price, please and thanks!

I just finished up these passenger peg plate brackets. Really happy how they turned out.

They mount with the factory muffler hanger hardware and rubber grommet. There’s 4 different ways you can mount it to set up how far the plate tucks under the tail.

Since they’re rubber mounted I made them as light as possible to keep them from shaking when you’re going over bumps in the road.

Other news, my garage at my house flooded enough during the tropical storm to get water inside the compressor of the turbo on Lucy. That put the water right at the bottom of the doors on my 240. Luckily, it was as easy as pulling the charge pipe and air filter off and just starting it so it could blow the water out of the turbo. The main shop got about 6” of water in it as well only on one half though. Only loss was some boxes that were destin for the dumpster anyways, and some drywall in my engine room.

And for those of you that didn’t see the post, here’s a video of how Lucy stacks up against an stage 1 rcc.

After that pull I bumped Lucy up 1psi on the ecu boost controller and she picked up 13hp. If you notice on the graph around 9k rpm the power drops off a little do to it being real fat up top. If that pull kept on the same progression as it did in the lower rpms, it would of made more power. I trimmed the fuel out, but I didn’t make another hit.

Once I pulled her off the dyno, I told brother C10 to take her for a ride. He was hesitant at first because he knew he would want to go turbo but it’s not in the cards for him right now. I was like “DUDE, YOURE NOT BUYING ANYTHING. GO BEAT THE poop OUT OF HER AND HAVE SOME FUN!!” He happily took the keys and went for a rip. The high speed recall showed he didn’t hold back either, lol.

Plans over the next 2 weeks if I have the time is to put new tires on now that I have finalized dyno numbers on pump gas. Then modify the top row of injectors. Doing this bumps the flow from 23lb/hr to around 65lb/hr. I’m doing this because I’m going to tune her on VP X98, and bump the boost up more. On 4.8-5 psi on X98 duty cycle is right at 90-93% @ 11,500 rpm. So going bigger on the injectors is a must if I want to run anymore boost. She made 268ish on 6 psi on 93. With the gains I usually see from swapping fuels I think 290-300whp is within reach. Being stock compression, I think I might take 7psi to get there. With all the octane, and cool burn, I’m not concerned about the head gasket. I think if anything those 16k mile stock valve springs will be the limiting factor. I’ll just have to play around with it and make sure it’s not floating the valves.

THEN it will be time to go to the track.

And for those of you that didn’t see the post, here’s a video of how Lucy stacks up against an stage 1 rcc.

After that pull I bumped Lucy up 1psi on the ecu boost controller and she picked up 13hp. If you notice on the graph around 9k rpm the power drops off a little do to it being real fat up top. If that pull kept on the same progression as it did in the lower rpms, it would of made more power. I trimmed the fuel out, but I didn’t make another hit.

Once I pulled her off the dyno, I told brother C10 to take her for a ride. He was hesitant at first because he knew he would want to go turbo but it’s not in the cards for him right now. I was like “DUDE, YOURE NOT BUYING ANYTHING. GO BEAT THE poop OUT OF HER AND HAVE SOME FUN!!” He happily took the keys and went for a rip. The high speed recall showed he didn’t hold back either, lol.

Plans over the next 2 weeks if I have the time is to put new tires on now that I have finalized dyno numbers on pump gas. Then modify the top row of injectors. Doing this bumps the flow from 23lb/hr to around 65lb/hr. I’m doing this because I’m going to tune her on VP X98, and bump the boost up more. On 4.8-5 psi on X98 duty cycle is right at 90-93% @ 11,500 rpm. So going bigger on the injectors is a must if I want to run anymore boost. She made 268ish on 6 psi on 93. With the gains I usually see from swapping fuels I think 290-300whp is within reach. Being stock compression, I think I might take 7psi to get there. With all the octane, and cool burn, I’m not concerned about the head gasket. I think if anything those 16k mile stock valve springs will be the limiting factor. I’ll just have to play around with it and make sure it’s not floating the valves.

THEN it will be time to go to the track.

Last edited:

Dopey

Registered

Just because I've read up on it but all old stuff mainly with cars but at some point if you ever change the rims and possibly bearings to something similar to what Brian has id like to see a pull with the stock vs aftermarket with only the wheels and bearings being different. Even if not on Lucy if you have any bikes that come in that you have the opportunity and could post video of the dyno pulls that'd be awesome.Other news, my garage at my house flooded enough during the tropical storm to get water inside the compressor of the turbo on Lucy. That put the water right at the bottom of the doors on my 240. Luckily, it was as easy as pulling the charge pipe and air filter off and just starting it so it could blow the water out of the turbo. The main shop got about 6” of water in it as well only on one half though. Only loss was some boxes that were destin for the dumpster anyways, and some drywall in my engine room.

View attachment 1605459

And for those of you that didn’t see the post, here’s a video of how Lucy stacks up against an stage 1 rcc.

After that pull I bumped Lucy up 1psi on the ecu boost controller and she picked up 13hp. If you notice on the graph around 9k rpm the power drops off a little do to it being real fat up top. If that pull kept on the same progression as it did in the lower rpms, it would of made more power. I trimmed the fuel out, but I didn’t make another hit.

Once I pulled her off the dyno, I told brother C10 to take her for a ride. He was hesitant at first because he knew he would want to go turbo but it’s not in the cards for him right now. I was like “DUDE, YOURE NOT BUYING ANYTHING. GO BEAT THE poop OUT OF HER AND HAVE SOME FUN!!” He happily took the keys and went for a rip. The high speed recall showed he didn’t hold back either, lol.

View attachment 1605460

Plans over the next 2 weeks if I have the time is to put new tires on now that I have finalized dyno numbers on pump gas. Then modify the top row of injectors. Doing this bumps the flow from 23lb/hr to around 65lb/hr. I’m doing this because I’m going to tune her on VP X98, and bump the boost up more. On 4.8-5 psi on X98 duty cycle is right at 90-93% @ 11,500 rpm. So going bigger on the injectors is a must if I want to run anymore boost. She made 268ish on 6 psi on 93. With the gains I usually see from swapping fuels I think 290-300whp is within reach. Being stock compression, I think I might take 7psi to get there. With all the octane, and cool burn, I’m not concerned about the head gasket. I think if anything those 16k mile stock valve springs will be the limiting factor. I’ll just have to play around with it and make sure it’s not floating the valves.

THEN it will be time to go to the track.

Let me know when you have one ready and I’ll buy, if the price won’t break the bankSorry for the delay. I have to tweak them just a touch. The spacing between the two groups of 9 holes is off by maybe 1/16”. Bolts slide through but at a slight angle. It bothers me... I have a bunch useful little aluminum parts/brackets in testing. I plan to do a big sale and roll them all out at once.

I just finished up these passenger peg plate brackets. Really happy how they turned out.

They mount with the factory muffler hanger hardware and rubber grommet. There’s 4 different ways you can mount it to set up how far the plate tucks under the tail.

Since they’re rubber mounted I made them as light as possible to keep them from shaking when you’re going over bumps in the road.

View attachment 1605446

View attachment 1605447

View attachment 1605448

View attachment 1605449

View attachment 1605450

View attachment 1605451

busakiller

Registered

Hmmm 240 from mn? Very curious how Lucy does with more boost on the e fuel.

I think I’m going to swap the wheels over off my grudge bike as I need a 16” front wheel anyways. I think it has standard bearings in them. As far as dyno comparisons I don’t think I’ll do it as I wouldn’t be able to do it the same day to keep the conditions close. Lighter wheels will always free up a few HP.Just because I've read up on it but all old stuff mainly with cars but at some point if you ever change the rims and possibly bearings to something similar to what Brian has id like to see a pull with the stock vs aftermarket with only the wheels and bearings being different. Even if not on Lucy if you have any bikes that come in that you have the opportunity and could post video of the dyno pulls that'd be awesome.

Let me know when you have one ready and I’ll buy, if the price won’t break the bank

I’ll have a post up. They’ll be less then $50 to stay on par with other options on the market.

Hmmm 240 from mn? Very curious how Lucy does with more boost on the e fuel.

Yep. I think I told you I have a lot of friends that live in echo, Marshall, and red wood. My best friend and I built that cat when we were 19 or 20. He was killed in a motorcycle crash 10 years ago, so I acquired the car from his family to finish it like he and I wanted to. Only thing I’ve done was put bigger cams in, sheet metal intake, with bigger TB, updated the fuel system for e85, and put an AEM series 2 on it. Makes 480hp 480tq on my mustang dyno, and weighs 2600lbs. Any car weighing 3000+ lbs, making less then 700whp doesn’t stand a chance against it. It makes a lot of people mad down here in Texas. If it’s not a GTR or Supra, it’s slow ricer junk to most guys.

As far as more boost on Lucy, I’m interested to see how much she can take on E98. I really wish I had more time available to mess with my own stuff. I would love to do just valve springs and see how far I could push it with stock compression with E98. Can tune around the possibility of pushing the head gasket, but as mentioned earlier, I think those 16k mile springs are more likely to be the limiting factor. I still think I can get her right to 300hp.

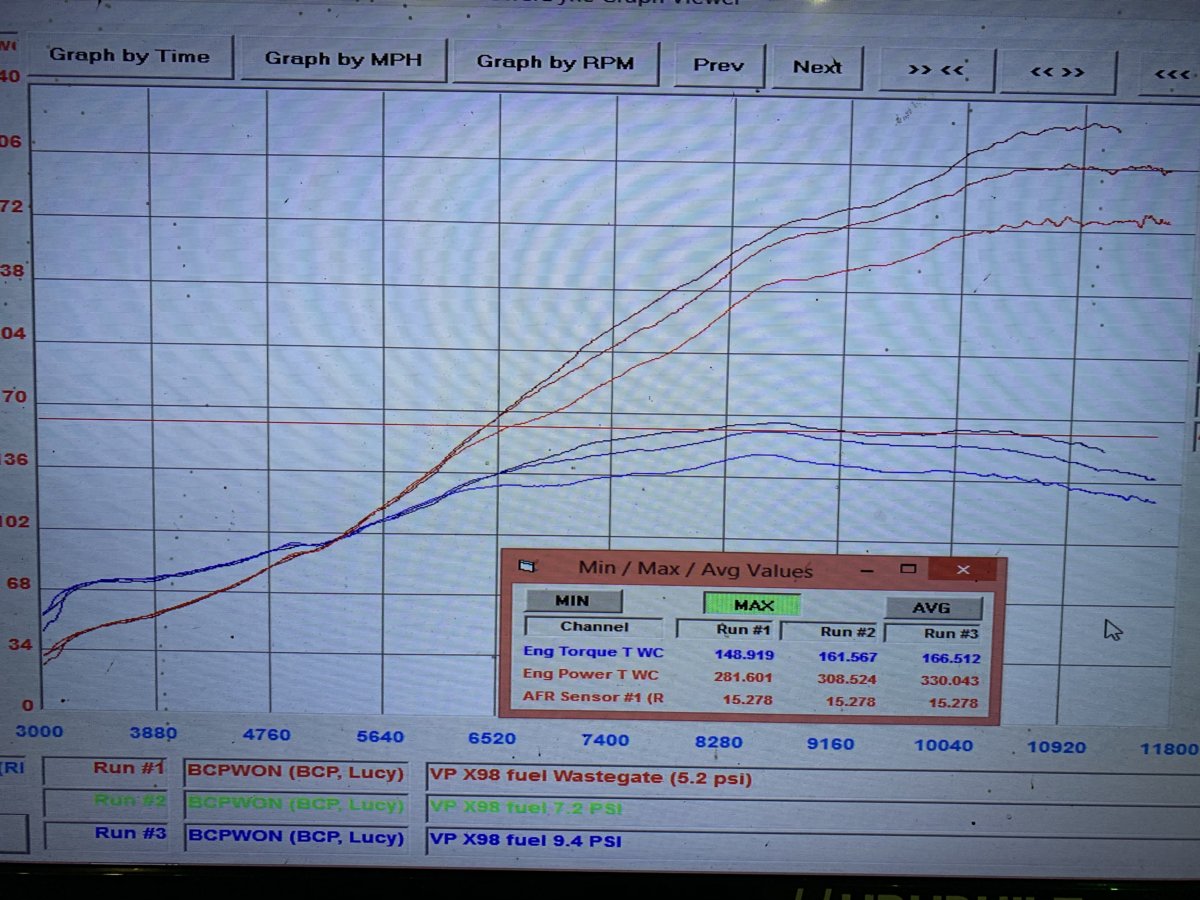

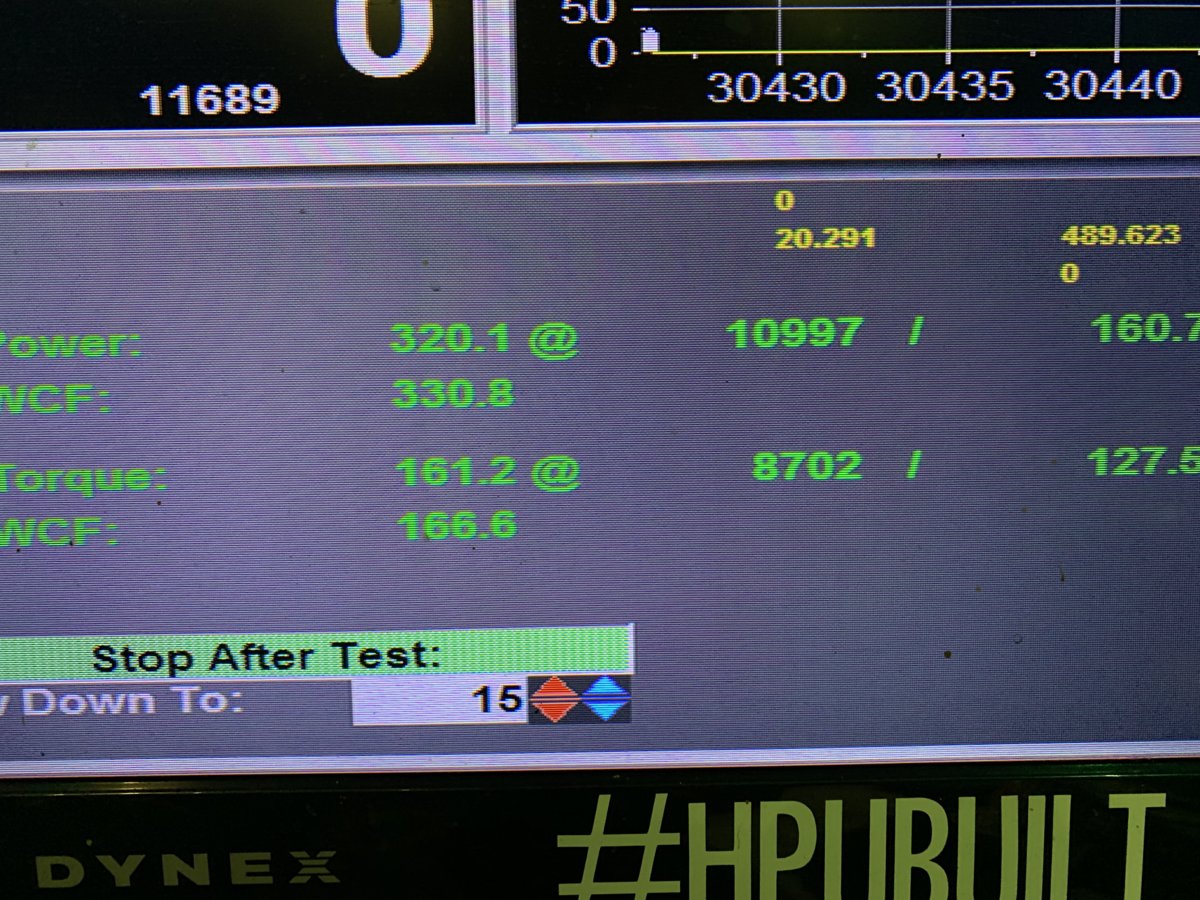

I let the cat out of the bag in another post, but as promised I turned up the boost on E98.

95 degrees in the dyno bay with a 2900ft DA.

The one thing I can definitely say is the gen 2 isn’t such on the ragged edge as previously thought. A lot of potential kit buyers express concern that their gen 2 won’t last very long because all they’ve read is that the compression is way to high for boost. With this test I can at least show them they can take a bit more. Yes there’s a big difference between these results and doing it on pump gas (which I wouldn’t do) I feel like I can ease some minds for the guys that were going to hold out for a base spacer too.

Since this video hit the internet a lot of people have been asking if the same results were possible on pump e85, or 100 octane. You guys know my feelings on pump e85. But I also would of attempted this on any regular gasoline including C16. Ethanol fuel burns so much cooler then any gasoline. The VP fuel also has 10% methanol mixed in. Aside from keeping the tune soft enough to not push the head gasket, the higher compression also means hotter combustion. So my next concern was keeping the piston rings cool enough that they didn’t expand, butt the ends together and break a piston.

That night I made 4 or 5 1/4 mile hits on the dyno, and 2 what I figured to be half mile hits. Never pushed water, and the engine still runs fine, so as of now, everything seems to be fine. I’ll be doing a compression and leakdown test to see if anything has changed since pre dyno inspection.

Also, if you guys didn’t notice I ceramic coated the exhaust. I used the VHT brand primer, paint, and flat clear. So far it seems to be holding up nicely. It requires a few heat cycles to get it completely cured if you don’t have an oven to run it through.

I can’t wait to get the plastics back on to go troll the local bike spot.

95 degrees in the dyno bay with a 2900ft DA.

The one thing I can definitely say is the gen 2 isn’t such on the ragged edge as previously thought. A lot of potential kit buyers express concern that their gen 2 won’t last very long because all they’ve read is that the compression is way to high for boost. With this test I can at least show them they can take a bit more. Yes there’s a big difference between these results and doing it on pump gas (which I wouldn’t do) I feel like I can ease some minds for the guys that were going to hold out for a base spacer too.

Since this video hit the internet a lot of people have been asking if the same results were possible on pump e85, or 100 octane. You guys know my feelings on pump e85. But I also would of attempted this on any regular gasoline including C16. Ethanol fuel burns so much cooler then any gasoline. The VP fuel also has 10% methanol mixed in. Aside from keeping the tune soft enough to not push the head gasket, the higher compression also means hotter combustion. So my next concern was keeping the piston rings cool enough that they didn’t expand, butt the ends together and break a piston.

That night I made 4 or 5 1/4 mile hits on the dyno, and 2 what I figured to be half mile hits. Never pushed water, and the engine still runs fine, so as of now, everything seems to be fine. I’ll be doing a compression and leakdown test to see if anything has changed since pre dyno inspection.

Also, if you guys didn’t notice I ceramic coated the exhaust. I used the VHT brand primer, paint, and flat clear. So far it seems to be holding up nicely. It requires a few heat cycles to get it completely cured if you don’t have an oven to run it through.

I can’t wait to get the plastics back on to go troll the local bike spot.

TurboBusa0704

Registered

It's coming along beautifully Rob, good jobI let the cat out of the bag in another post, but as promised I turned up the boost on E98.

95 degrees in the dyno bay with a 2900ft DA.View attachment 1605906

View attachment 1605907

The one thing I can definitely say is the gen 2 isn’t such on the ragged edge as previously thought. A lot of potential kit buyers express concern that their gen 2 won’t last very long because all they’ve read is that the compression is way to high for boost. With this test I can at least show them they can take a bit more. Yes there’s a big difference between these results and doing it on pump gas (which I wouldn’t do) I feel like I can ease some minds for the guys that were going to hold out for a base spacer too.

Since this video hit the internet a lot of people have been asking if the same results were possible on pump e85, or 100 octane. You guys know my feelings on pump e85. But I also would of attempted this on any regular gasoline including C16. Ethanol fuel burns so much cooler then any gasoline. The VP fuel also has 10% methanol mixed in. Aside from keeping the tune soft enough to not push the head gasket, the higher compression also means hotter combustion. So my next concern was keeping the piston rings cool enough that they didn’t expand, butt the ends together and break a piston.

That night I made 4 or 5 1/4 mile hits on the dyno, and 2 what I figured to be half mile hits. Never pushed water, and the engine still runs fine, so as of now, everything seems to be fine. I’ll be doing a compression and leakdown test to see if anything has changed since pre dyno inspection.

Also, if you guys didn’t notice I ceramic coated the exhaust. I used the VHT brand primer, paint, and flat clear. So far it seems to be holding up nicely. It requires a few heat cycles to get it completely cured if you don’t have an oven to run it through.

I can’t wait to get the plastics back on to go troll the local bike spot.View attachment 1605908

View attachment 1605909

I Don’t know such a trashy looking bike manages to look good in every pic I take of it.

The ceramic black exhaust works so well.

c10

Registered

Needs a rear brakeView attachment 1606066

I Don’t know such a trashy looking bike manages to look good in every pic I take of it.

The ceramic black exhaust works so well.

Yep, gotta be able to brake boost on those highway rolls.Needs a rear brake

It’s a gen 1 arm so I’ll have to build something to work if I keep that arm on the bike.

I took the wheels off the grudge bike as it’s going to get some bst’s with a 16” front.

What an improvement.

What an improvement.

They’re RK Excel, pro series. They’re forged aluminum, and then hard anodized.Sick wheels, what model are they?

I bought them used off of psychobike a few years ago. Up until that point I had never seen them before, apparently most guys haven’t. They’ve been discontinued for several years now, but I wonder why. There’s one site I found that still has the listing up and they were only $1600 for the set... or maybe that’s why, they weren’t making any money.

I have customers that try to buy them from me all the time. One guy even offered me almost enough to cover the new bst wheels for the grudge bike. I figured if they’re that rare and guys like them that much that I better hang on to them. Being that Lucy is rolling advertisement for the shop, they’re a good convo starter for potential customers.

busakiller

Registered

The bike does look very nice in the pictures.

michael parris heuberger

Registered

HI. I still like my DYMAG wheels. They are a bout 20% heaver than CF. I have had many sets on bikes and cars. I did have one crack on the front wheel on my ZX1100. I never had a problem on my T 142 LOLA F5000 even when I crashed at 160 MPH at Mosport.Sick wheels, what model are they?

She could catfish you real quick. LolThe bike does look very nice in the pictures.