So a bit of an update. After some extensive updates and repairs, I was able to fire the bike up for the first time on Sunday.

I managed to track down the cause of the of the drivability issue pretty quickly. This bike had an old school FMU on it, and was tuned with a power commander instead of using a 1:1 regulator, and 3 bar map sensor. Being that this bike was probably built in 09, at that time, ECU editor wasn’t up to par yet to run the bike on a 3 bar, and 1:1, so that’s why the first kits for the 08 busas from RCC came with an fmu.

When the bike arrived I immediately put a data logger on it, and a fuel pressure gauge since proper fueling on fmu equipped bikes is largely dependent on the boosted fuel pressure. (1:8 ratio) I found when slowing rolling on to the throttle like you would do pulling out in front of traffic the bike got to a point where it would shutter pretty badly. When this condition occurred the wideband was showing severely lean condition going as high as 16.8 afr.

When this was happening was when Boost was at 2-3psi. The boost gauge/logger was tied in to the boost signal for the fmu. While watching the fuel pressure guage, I noticed that the fuel pressure wouldn’t start to increase until the boost pressure was over 4psi. Base fuel pressure was 45psi warm at idle. If you look at the still pic from the video you can see Boost is at at least 2psi, while fuel pressure is still showing 45psi. However if you just hang the throttle it would shoot right through that trouble area smoothly and the would pick up well, but “hit” you normally feel with a RCC stage 1-2 turbo seemed a bit soft even by lowered compression engine standards.

The next thing that stood out was the boosted fuel pressure. The fuel pressure gauge reads to 100psi, and the needle stop is probably at 120-130psi. By 8psi, the gauge was already pegged out, and the boosted afr’s were in the mid 10’s. Big problem with such high fuel pressure is fuel injectors lose their ability to close after 100psi. So the injectors were just hanging wide open dumping fuel. I didn’t run a pull out to redline, but I saw as much as 12psi of Boost before letting off which gave me my next clue.

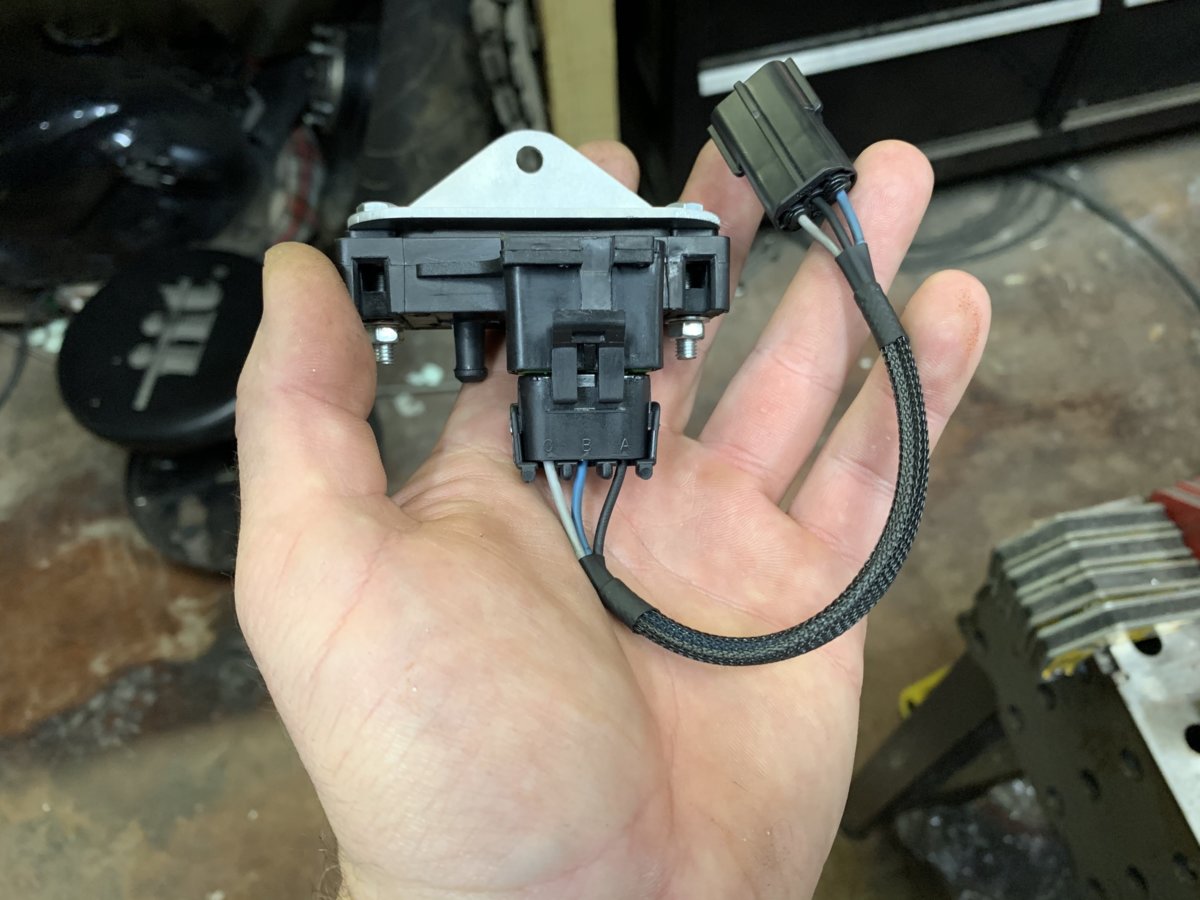

The bike had an old style begi FMU which use metal shims inside to help with controlling boosted fuel pressure. When used within their intended limits of 10psi or less, they’re generally pretty reliable. But, when pushed past that limit, the metal shims wear quickly, or crack causing fueling issues.

So I took the fmu apart to inspect the shims, and found the shims to be damaged.

If you notice, right in the middle its got a little bit of a dome. This is why the fuel pressure wouldn’t go until after 3psi. The boost had to overcome the preload (I guess you could call it) if the bent shim before pressure would rise to fuel properly. I would venture to guess this was a result of running too much boost, and too high of fuel pressure. I pulled the spring out of the wastegate, and it was a 14psi spring.

Pretty much as soon as I saw the bike had an fmu on it I told Jack that no matter if the problem or not, we were going to ditch it along with the power commander to bring the fueling system out of the Stone Age. Since the Bking uses a gen 2 busa engine, and electronics there’s no reason not to put a 1:1 regulator, 3 bar map sensor on the bike, and tune it through the ecu. So I built a completely new fuel system, and mounted the new fuel pump under the tail to keep it from vapor locking, and free up space under the tank. The bkings have probably 1/3 less space under the tank the the busas do.

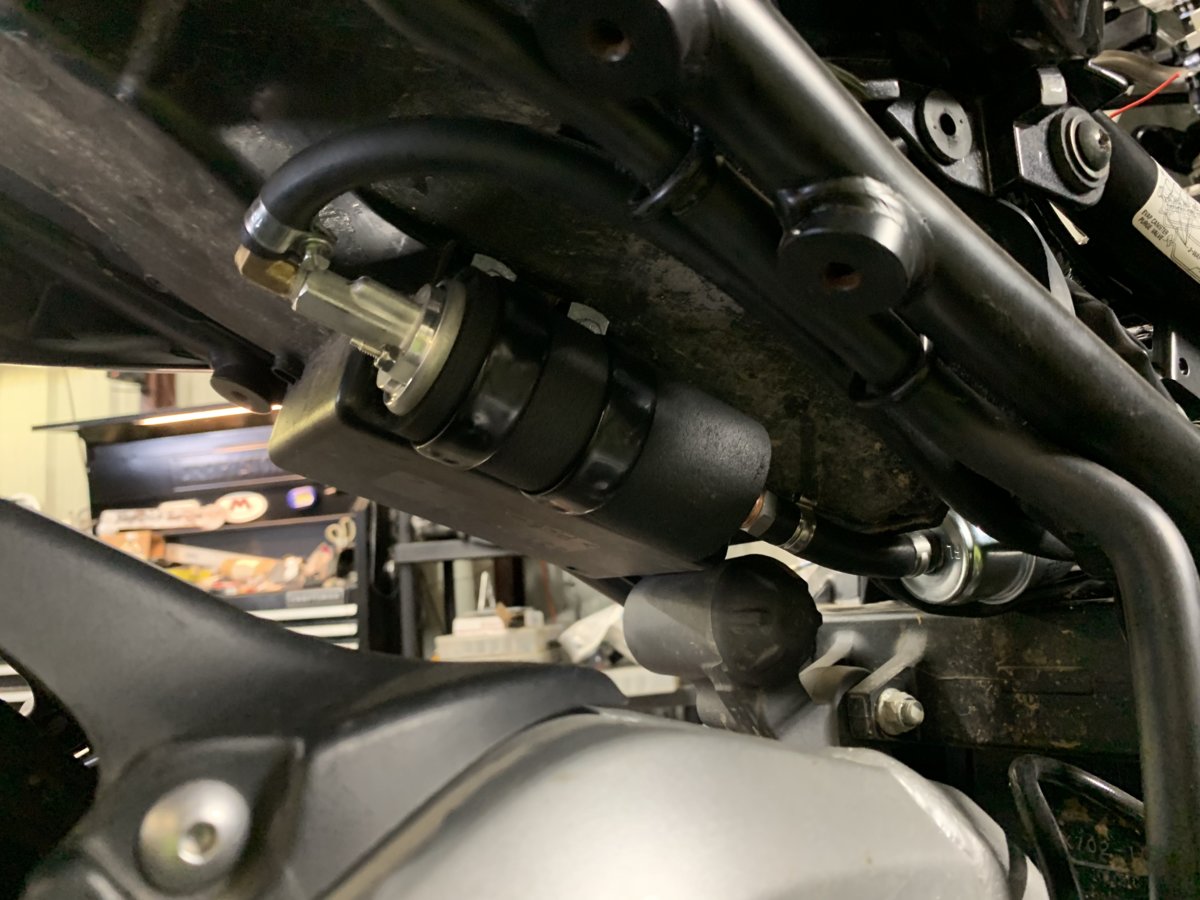

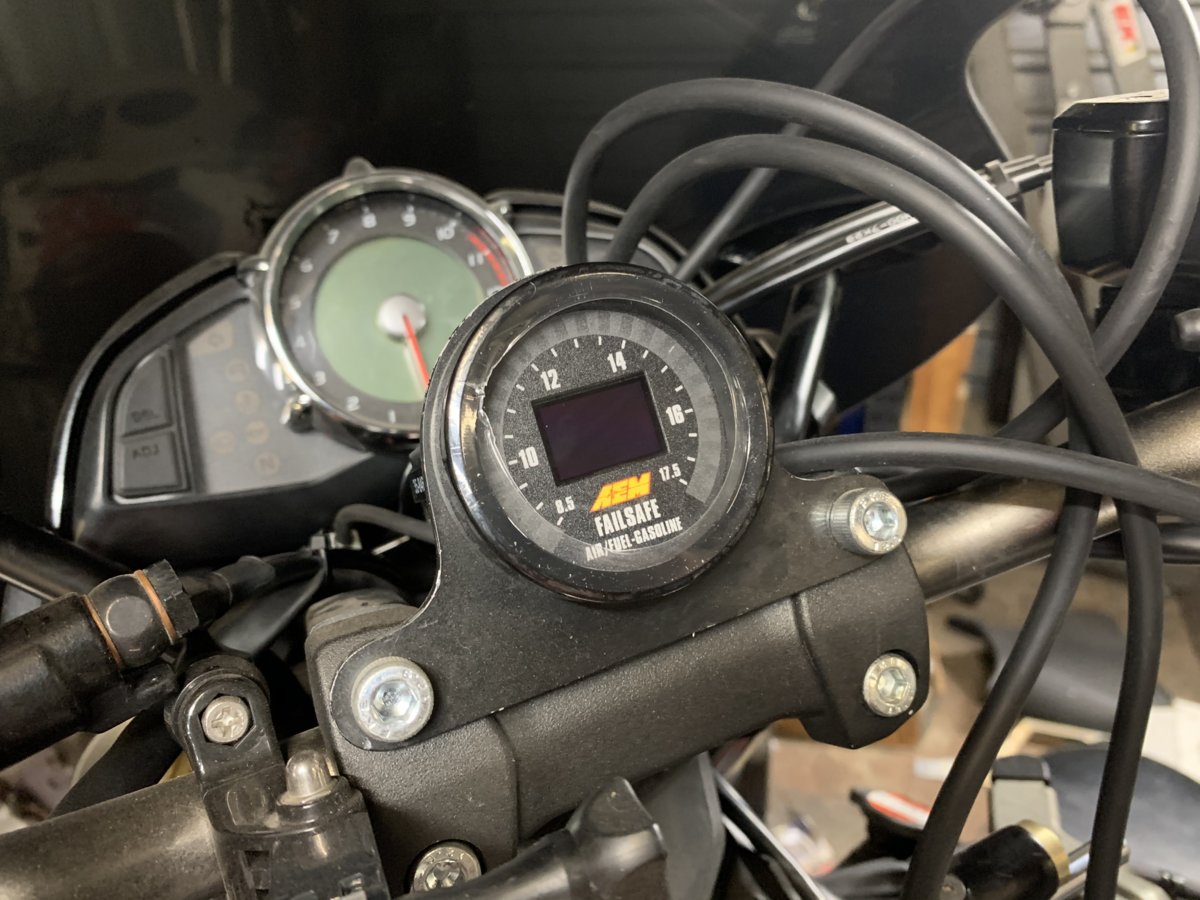

Then fitted it with one of my 3bar map sensors, bracket, and adapter harness. I also installed one of my plug and play boost control solenoids so we can use boost by gear, controlled by the stock Ecu. The bike had a mechanical boost gauge on it as well but we decided to ditched that for an AEM wideband failsafe. Digital afr, boost, and internal data logger built in. It also as programmable safety’s that work well with methanol injection.

Since space on this bike is of a premium, the bike has a built engine, and a turbo capable of over 400hp, being efficient with methanol usage was also a concern of mine. The bike had an old school progressive style RCC meth kit installed. But the progressive part of the system was based off of rpm, not boost level like modern controllers. I also doubted how effective the meth kit really based off of how the small maybe 1/2 quart tank was mounted. It was mounted to the outlet of the tank where fluid gets sucked down to the pump was facing the front of the bike. Meaning it was pretty likely that after the tank was emptied to a certain point, the methanol pump was probably sucking air as the methanol moved to the back of the tank under heavy acceleration. I started to come up with a few ideas for a larger tank that would have fit in the factory swingarm where the exhaust passed through, but ultimately after telling jack how much power I expected the bike to make now, he opted to put a longer swing arm on it. That ended up working out well as it’s getting the same arm I put on the supercharged king I built awhile back. I just so happen to have a meth tank that holds the pump internally already designed and tested. That tank has been doing great on the supercharged bking.

Lastly, one thing I noticed when the bike arrived and I first started it was like a ratteling sound or exhaust leak. I took the air filter off and found some excessive shaft play in the turbo. Then I noticed some carbon build up above the turbo flange on the header. That’s where I found one of the runners on the header cracked almost completely around. Remember I said the bike didn’t seem to hit as hard as it should? Well a big exhaust leak will give that effect. That also explains why the boost readout from franks dyno looks like its boost creeping. It hit 12psi by 6k rpm, but didn’t hit 14psi until redline. I was able to clean the crack up and reweld it. Shouldn’t even crack there again.

The turbo center section was sent out to Turbos Direct for a rebuild to which they noticed the tips of the turbine wheel were missing from rubbing on the edge of the exhaust housing.