You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

busa fighter build

- Thread starter spart666

- Start date

More options

Meta tagsspart666

Registered

some help guys

loads of niggly probs all now sorted

was up at bills for a couple of days utilising his dyno

got the leads for the ecu, software, holeshots mapping ect

try to keep this short

mapping is pretty spot on tick over is now spot on not hunting for fuel

running rich at approx 8k revs

the problem is not boosting

using an eboost 2 which is set to 8psi but when on the dyno only getting about 3.5 psi

wastgate is working blow off valve working no cracks in plen chamber headers not cracked all plumbing checked and correct turbos running

mappings correct

any ideas ?

have been told what it possibly could be but before i post it wanna see what you guys think

heres the spec

fully stripped and rebuilt new mains and big ends

cylinder head had the valve seats re-cut and lapped and some minor porting

bearings and seals heavy duty headstuds

heavy duty clutch springs

forged je pistons, barrel spacer

modded clutch basket billet clutch slave support bracket

garrett gt25 turbo charger

tial 38mm wastegate

small dump pipe k&n cone filter

alloy plenham chamber

fuel m,ment MBE 9A4 ECU

MODIFIED HARNESS TO SUIT ECU

3 BAR MAP SENSOR

h/d FUEL PUMP

HEAVY DUTY FUEL INJECTORS

TOP HATS AND CLIPS

EBOOST 2 BOOST CONTROLLER

NEW REGULATOR/RECTIFIER

ohhhhh yea and a vid of bill giving it some

loads of niggly probs all now sorted

was up at bills for a couple of days utilising his dyno

got the leads for the ecu, software, holeshots mapping ect

try to keep this short

mapping is pretty spot on tick over is now spot on not hunting for fuel

running rich at approx 8k revs

the problem is not boosting

using an eboost 2 which is set to 8psi but when on the dyno only getting about 3.5 psi

wastgate is working blow off valve working no cracks in plen chamber headers not cracked all plumbing checked and correct turbos running

mappings correct

any ideas ?

have been told what it possibly could be but before i post it wanna see what you guys think

heres the spec

fully stripped and rebuilt new mains and big ends

cylinder head had the valve seats re-cut and lapped and some minor porting

bearings and seals heavy duty headstuds

heavy duty clutch springs

forged je pistons, barrel spacer

modded clutch basket billet clutch slave support bracket

garrett gt25 turbo charger

tial 38mm wastegate

small dump pipe k&n cone filter

alloy plenham chamber

fuel m,ment MBE 9A4 ECU

MODIFIED HARNESS TO SUIT ECU

3 BAR MAP SENSOR

h/d FUEL PUMP

HEAVY DUTY FUEL INJECTORS

TOP HATS AND CLIPS

EBOOST 2 BOOST CONTROLLER

NEW REGULATOR/RECTIFIER

ohhhhh yea and a vid of bill giving it some

spart666

Registered

Hi guys

aint posted for a while because all weve managed to do is find problems but we are getting there

last post we had the bike boosting pushing 242bhp @ 8 psi bill (Mustapha dump to you lot)

couldent get the bike to boost higher than 8 psi so reckoned since the wiring loom has been hacked about so many times could be creating an issue with the eboost

his answer redo it he got rid of the over complicated eboost i got hold of some new guages

and sorted them to fit bill rewired them and cut another hole in my tank

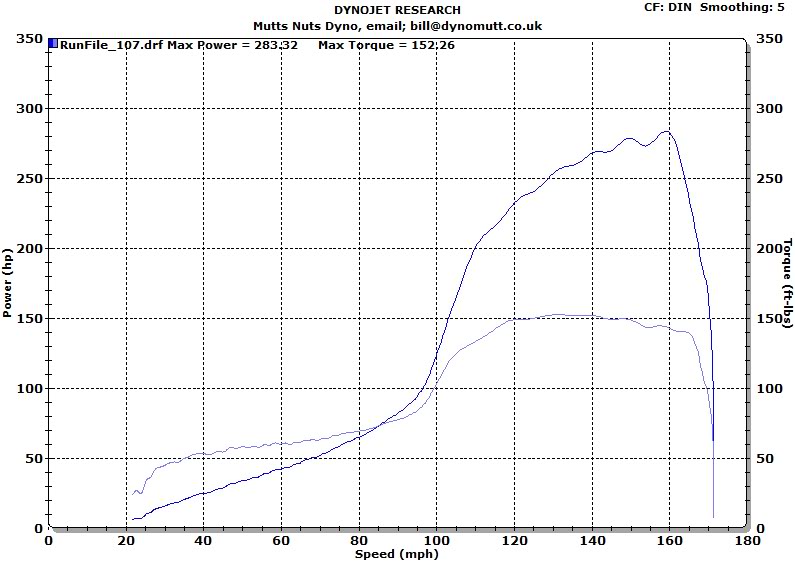

result was 288bhp 160lb/ft at 12 psi.

bill says "This was the first test of the new boost control system.

The new spec is

1st stage 8psi on the wastegate spring alone 240bhp, push the button and 2nd stage is engaged which sends boost pressure to the top of the diaphram, when the boost pressure reaches the desired level the adjustable boost pressure switch in the plenum

switches the 3 way air solenoid and the wastegate opens, the new system allows boost pressure from 8 to 18 psi, simply by winding in the adjuster on the pressure switch in the pleneum. The system is designed that in the event of power failure or component failure the boost will default to the low setting

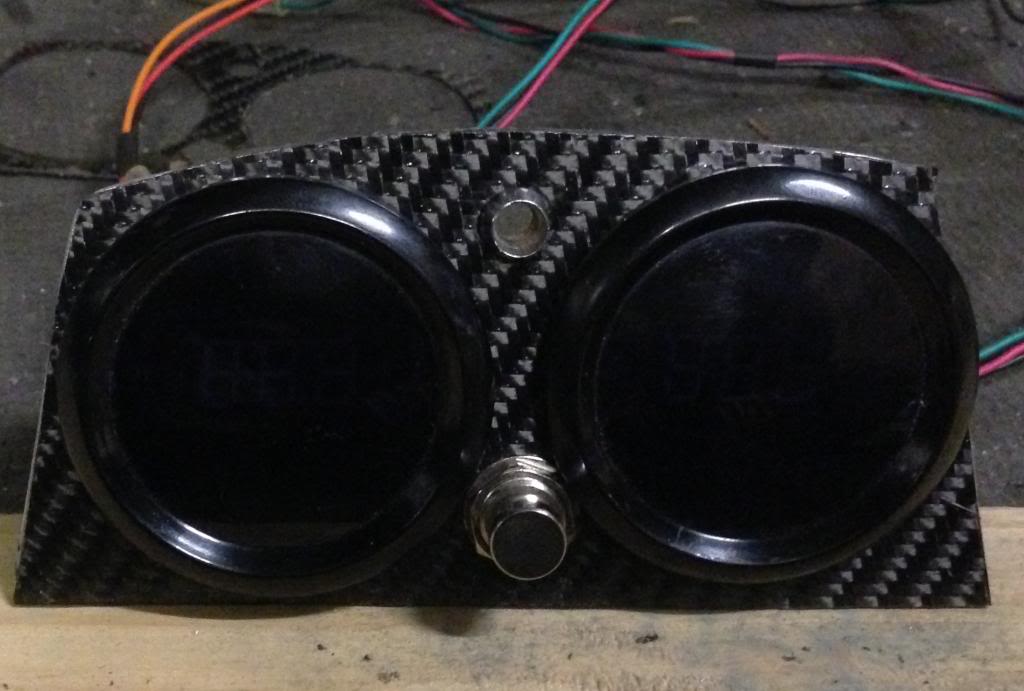

A latching push button is mounted between the new digital boost gauge and matching digital temp gauge supplied by Visual Performance, when the 2nd stage is active a red warining LED in between the gauges illuminates, this LED goes out when the wastegate opens.

seperate subloom was built for the new boost control to avoid having to do anything to the existing wiring system. The valve clearances on several of the intake valves were far too tight and the intakes were holding open slightly when the motor got hot.

The graph attatched was the first test of the new system and managed 288bhp and 160lb/ft of torque at 12psi.

on high boost, bill was going to turn the boost up and get it to 300bhp but the ****ing wiring gremlins have raised there ****ing heads again bill managed a couple of runs but the ignition keeps breaking down one minute its fine next not

result you touch the wiring loom you dont know if the bike will start or not or how its going to behave and to give bill his due his worry is it fails me whilst im overtaking or mid corner ect ect

the other major point is we want realiability so got to bite the bullet

pretty sure bill will add his two pence worth at some stage

so blasted off an email to jack at holeshot with the issues and the result

a full wiring harness for mbe ecu

Injector Sub loom

Map sensor input loom

and bill is going to build a seperate loom for the lights ect

hes already built a subloom for the boost control part of system

so when we get this sorted bill can finally map it in and fine tune it

aint posted for a while because all weve managed to do is find problems but we are getting there

last post we had the bike boosting pushing 242bhp @ 8 psi bill (Mustapha dump to you lot)

couldent get the bike to boost higher than 8 psi so reckoned since the wiring loom has been hacked about so many times could be creating an issue with the eboost

his answer redo it he got rid of the over complicated eboost i got hold of some new guages

and sorted them to fit bill rewired them and cut another hole in my tank

result was 288bhp 160lb/ft at 12 psi.

bill says "This was the first test of the new boost control system.

The new spec is

1st stage 8psi on the wastegate spring alone 240bhp, push the button and 2nd stage is engaged which sends boost pressure to the top of the diaphram, when the boost pressure reaches the desired level the adjustable boost pressure switch in the plenum

switches the 3 way air solenoid and the wastegate opens, the new system allows boost pressure from 8 to 18 psi, simply by winding in the adjuster on the pressure switch in the pleneum. The system is designed that in the event of power failure or component failure the boost will default to the low setting

A latching push button is mounted between the new digital boost gauge and matching digital temp gauge supplied by Visual Performance, when the 2nd stage is active a red warining LED in between the gauges illuminates, this LED goes out when the wastegate opens.

seperate subloom was built for the new boost control to avoid having to do anything to the existing wiring system. The valve clearances on several of the intake valves were far too tight and the intakes were holding open slightly when the motor got hot.

The graph attatched was the first test of the new system and managed 288bhp and 160lb/ft of torque at 12psi.

on high boost, bill was going to turn the boost up and get it to 300bhp but the ****ing wiring gremlins have raised there ****ing heads again bill managed a couple of runs but the ignition keeps breaking down one minute its fine next not

result you touch the wiring loom you dont know if the bike will start or not or how its going to behave and to give bill his due his worry is it fails me whilst im overtaking or mid corner ect ect

the other major point is we want realiability so got to bite the bullet

pretty sure bill will add his two pence worth at some stage

so blasted off an email to jack at holeshot with the issues and the result

a full wiring harness for mbe ecu

Injector Sub loom

Map sensor input loom

and bill is going to build a seperate loom for the lights ect

hes already built a subloom for the boost control part of system

so when we get this sorted bill can finally map it in and fine tune it

Stainless Steve

Registered

I had all sorts of problems with my car loom, but the dedicated MBE loom sorted it all out. I run a 9A4 like you.

Good luck with it mate.

Good luck with it mate.

spart666

Registered

Hi all

quick update bikes was on the backburner for a while no funds new job and major doggy surgery was going to sell it off but got talked out of it bill called me a few choice names and spouting stuff like you know how much time ive spent on that you kent or something like that

and busa dave just said we will sort it no dramas

this was my turbo rebuild £1000 worth of stiching ouch!!!!

bill finishing up the mapping when i sort the oil return on the turbo and fit a one way check valve as its to low

now sorted just waiting for the check valve then i can whip off the turbo and get the oil seals done

when we got the bike home the bike would.nt fire up changed the battery still no joy

bikes was running rich so checked fuel pressure electrics bill done a sterling job changed the fuel lines as they needed re-routing all good

pulled the air filter off that wasent helping ****ed so needs replacing

rigged up the laptop and error was bad tooth pattern talked to sbd who were brilliant sent them the map and he emailed me back with a tweeked map all in 10 mins loaded it back on

bike starts first time every time

doing some detail stuff on it over the next couple of months keep you posted

quick update bikes was on the backburner for a while no funds new job and major doggy surgery was going to sell it off but got talked out of it bill called me a few choice names and spouting stuff like you know how much time ive spent on that you kent or something like that

and busa dave just said we will sort it no dramas

this was my turbo rebuild £1000 worth of stiching ouch!!!!

bill finishing up the mapping when i sort the oil return on the turbo and fit a one way check valve as its to low

now sorted just waiting for the check valve then i can whip off the turbo and get the oil seals done

when we got the bike home the bike would.nt fire up changed the battery still no joy

bikes was running rich so checked fuel pressure electrics bill done a sterling job changed the fuel lines as they needed re-routing all good

pulled the air filter off that wasent helping ****ed so needs replacing

rigged up the laptop and error was bad tooth pattern talked to sbd who were brilliant sent them the map and he emailed me back with a tweeked map all in 10 mins loaded it back on

bike starts first time every time

doing some detail stuff on it over the next couple of months keep you posted

spart666

Registered

hi all

some updates bikes back on turbos gone off to be rebuilt

wiring all sorted headlight brackets being made up out of billett

turbo guages redone and new surround made of to be mapped and sorted by feb

dave sorting out a headlight cover in the next two weeks

now the bad news

so how to put this

This isn't about sadness its about a celebration

those of you who know spart the boxer

was a big 9 stone white boxer 12 years old with a massive heart

always in trouble and my best friend he grew up

with my daughter and was the centre of our lives

In August he had a big op and he pulled through however as fate would have it

the tumor grew back

i wanted more than anything spart to have this xmas with us

so the stubborn bastard started perking up gave me my wish

at 4 pm on xmas day he went for his normal walk and had a heart attack and

died in the field where we have walked him for 12 years

so I got my wish the best xmas present that I could have got

With that i want all that knew him to offer up a big bigup for

spart and may he cause havoc in the afterlife

rest in peace mate xxxxx

some updates bikes back on turbos gone off to be rebuilt

wiring all sorted headlight brackets being made up out of billett

turbo guages redone and new surround made of to be mapped and sorted by feb

dave sorting out a headlight cover in the next two weeks

now the bad news

so how to put this

This isn't about sadness its about a celebration

those of you who know spart the boxer

was a big 9 stone white boxer 12 years old with a massive heart

always in trouble and my best friend he grew up

with my daughter and was the centre of our lives

In August he had a big op and he pulled through however as fate would have it

the tumor grew back

i wanted more than anything spart to have this xmas with us

so the stubborn bastard started perking up gave me my wish

at 4 pm on xmas day he went for his normal walk and had a heart attack and

died in the field where we have walked him for 12 years

so I got my wish the best xmas present that I could have got

With that i want all that knew him to offer up a big bigup for

spart and may he cause havoc in the afterlife

rest in peace mate xxxxx

spart666

Registered

thought it was time to update

first up say hello to henry the thug a white boxer black eye and a mohawk will never replace spart but we had this gap which just had to be filled

turbo got sorted new seals which were shot and all cleaned up and balanced

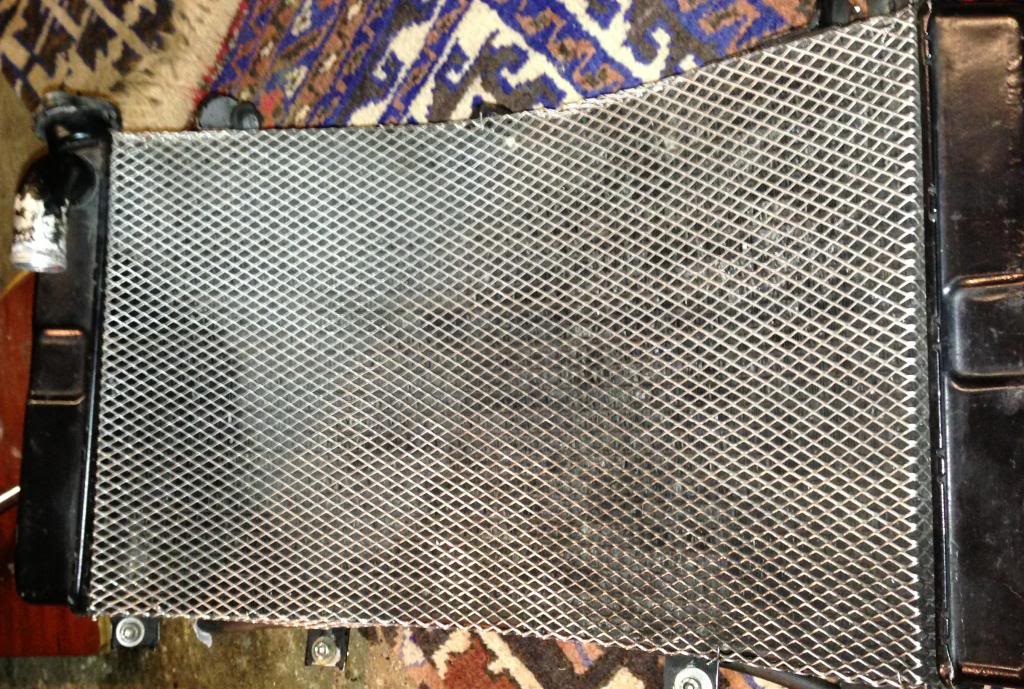

whilst i was at it repainted the engine block and sorted out that crap radiator

redone the clocks with a decent piece of carbon fiber

got some more space in the engine bay and changed the standard engine breather with a low profile unit loads of room now

so with that lot done bike was sent off to tim who mapped the bike problem we had was that the bike was running really rich and on power felt like we had a fueling problem all was checked that we could check busa dave went through it with a fine toothcombe all was good so when tim got it within 5 mins on the dyno sussed the prob tps was wired wrong that sorted bike was mapped and running lovely 230bhp low boost

still got to map high boost but we need to rewire that part as tim wasent happy with the set up so thats a job for him after summer

so all thats left for me to do noz bottle powdercoated being done this week new air filter ordered brackets for lights being done this week new lock up clutch on order due next two weeks

first up say hello to henry the thug a white boxer black eye and a mohawk will never replace spart but we had this gap which just had to be filled

turbo got sorted new seals which were shot and all cleaned up and balanced

whilst i was at it repainted the engine block and sorted out that crap radiator

redone the clocks with a decent piece of carbon fiber

got some more space in the engine bay and changed the standard engine breather with a low profile unit loads of room now

so with that lot done bike was sent off to tim who mapped the bike problem we had was that the bike was running really rich and on power felt like we had a fueling problem all was checked that we could check busa dave went through it with a fine toothcombe all was good so when tim got it within 5 mins on the dyno sussed the prob tps was wired wrong that sorted bike was mapped and running lovely 230bhp low boost

still got to map high boost but we need to rewire that part as tim wasent happy with the set up so thats a job for him after summer

so all thats left for me to do noz bottle powdercoated being done this week new air filter ordered brackets for lights being done this week new lock up clutch on order due next two weeks

Last edited by a moderator:

spart666

Registered

took out the bike over the weekend found that on tickover it was hunting and what sounded like an air leak

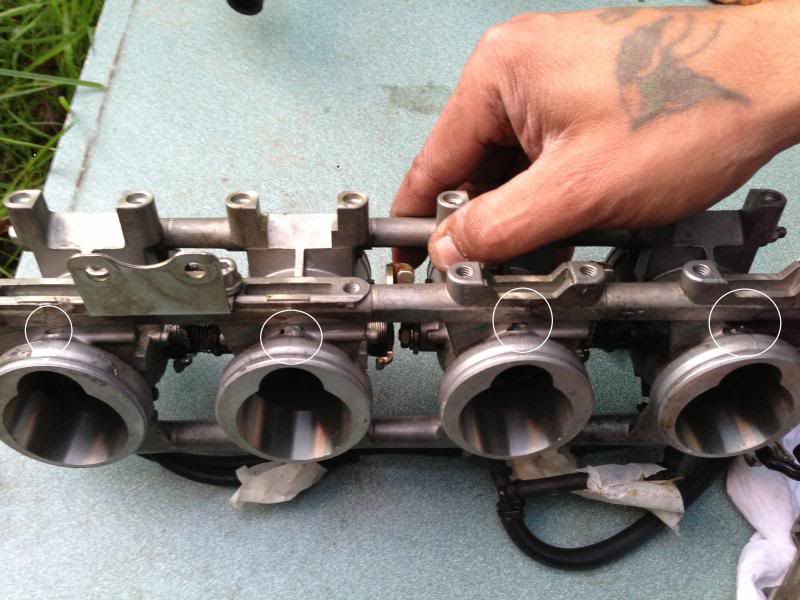

so gave mr bruno a shout had a good look around and found no leaks from the turbo system but what was concerning was throttle body no4 was lifting

first thoughts bad spark ruled that out then coil breakdown again ruled out as we went through every thing i spoted a spark from the inside of the engine bay dave then investigated and spoted the vapour coming out of the bottom of the throttle body checked the rubbers all fine so somehow i had a hole in the throttle body

cut a long story short we went looking for a second hand set just so happened dave had a spare set of busa throttle bodys in his garage as you do

the scary bit was what we found

1.the hole for the injectors were not drilled out correctly every single hole had damage which someone had sealed with sealent on one side

and on the other the had used chemical metal to seal and then repainted them

2. throttle body four was resembling a combustion chamber

3.even the boots mounting to the engine were silocined it looks like someone tried everything to stop any leaks couldent have been much worse just lucky we caught it in time

result

a nice new pair we replaced the boots all the lines the injector holes were already properly drilled out bike started first time all balanced no air leaks not hunting off the road for 24hours many thanks dave

so gave mr bruno a shout had a good look around and found no leaks from the turbo system but what was concerning was throttle body no4 was lifting

first thoughts bad spark ruled that out then coil breakdown again ruled out as we went through every thing i spoted a spark from the inside of the engine bay dave then investigated and spoted the vapour coming out of the bottom of the throttle body checked the rubbers all fine so somehow i had a hole in the throttle body

cut a long story short we went looking for a second hand set just so happened dave had a spare set of busa throttle bodys in his garage as you do

the scary bit was what we found

1.the hole for the injectors were not drilled out correctly every single hole had damage which someone had sealed with sealent on one side

and on the other the had used chemical metal to seal and then repainted them

2. throttle body four was resembling a combustion chamber

3.even the boots mounting to the engine were silocined it looks like someone tried everything to stop any leaks couldent have been much worse just lucky we caught it in time

result

a nice new pair we replaced the boots all the lines the injector holes were already properly drilled out bike started first time all balanced no air leaks not hunting off the road for 24hours many thanks dave

Last edited by a moderator:

Similar threads

- Replies

- 10

- Views

- 1,795

You have skills my friend!

You have skills my friend!